November 2015

JAMES MOORE, IrriCheck

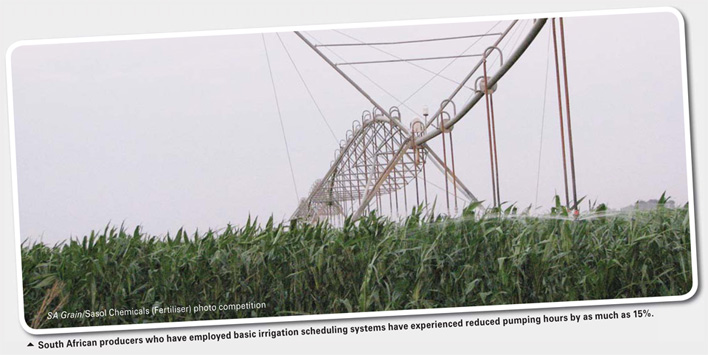

With the persistent and rapid rise in energy costs and increased pressure on our water resources, the South African irrigation producer is, now more than ever, faced with the problem of how to produce more, with less, and to make every drop count.

To add to this, producers have to face an uneven electricity supply, dubbed “load shedding”, which adds to the pressure by limiting the hours available to irrigate.

Mr Gerrit (Appel) van Zyl, a partner at IrriCheck (Pty) Ltd, is an engineer and irrigation design and scheduling specialist with more than 20 years’ experience. He reveals that, “On average (depending on the distance and height at which the water is pumped) it can cost R1 526 per hectare in electricity alone to grow a maize crop. To put this into perspective, in 2005/2006 the comparative cost was R515,41 and in 2010/2011 it stood at R1 047,60. This is an increase of, on average, 20% per year. Next year, with a 12,69% increase, this cost will rise to R1 719,65 per hectare and the subsequent year to R1 937,87 per hectare.”

In order to be sustainable, producers are rapidly introducing new technologies to improve their effectiveness and yields. In the irrigation farming environment, irrigation scheduling appears to be the most popular and effective way to achieve that.

What is irrigation scheduling?

According to Van Zyl, irrigation scheduling is best described as the process where technologies are employed to manage the soil-cropclimate- economic environment by measuring and calculating the optimum quantity and timing of irrigation.

This, in combination with the limitations of the irrigation system, is used to apply water at the correct rate and in accordance with crop phenological stages in order to maximise water and nutrient use efficiency, while maximising production and quality.

Why schedule?

Crop water use is influenced by many factors, including, but not limited to; the climate, the type and size of the crop, crop phenology, the root system, soil characteristics and irrigation systems. Most of these factors are variable and interdependent on one another.

“When irrigation producers are unsure when or how much to irrigate, they tend to over-irrigate,” says Van Zyl. “Every time we overirrigate, precious water and nutrients are washed away (leached) past the root zone and out of the plant’s reach. In addition to this, soil oxygen, vital for healthy root growth and beneficial microbial activity is constantly impaired, potentially leading to anaerobic conditions which inhibits the uptake of water and nutrients and creates favourable conditions for soil borne diseases, ultimately decreasing yield potential.”

Irrigation scheduling systems

Currently, the most popular irrigation scheduling hardware is the continuous logging soil moisture capacitance probe, which is coupled with a GPRS unit. It measures the soil moisture content and temperature at six depths receiving live data on a two hour basis.

As for software, Van Zyl is of the opinion that an efficient scheduling system should at least have the ability to measure and analyse the following:

Soils

Each soil has unique boundaries in terms of water holding capacity, including field water capacity (FWC), permanent wilting point (PWP) and readily available water (RAW). Knowing these boundaries is important when managing different moisture uptake regimes at key phenological stages of the crop as well as when applying (safe) controlled stress conditions for crop manipulation. Most importantly, the system should indicate soil water data in millimetres of water, and probes should therefore be calibrated to millimetres per meter water holding capacity in each field.

Crop specific water needs

The software should accurately simulate crop evapotranspiration under non-specific conditions, using the dual crop coefficient approach. Daily water loss in the form of transpiration from the crop and evaporation from the soil under specific in situ climatic conditions should be taken into consideration. Because of changing management practices, crop phenology and climatic conditions, the software should also be able to automatically determine the crop evapotranspiration and changing crop coefficients according to these changing conditions for scheduling purposes.

Climatic parameters

Because atmospheric evaporative demand is the driving force in crop water use, it is important that an accurate weather forecast is used for predicting irrigation needs for the coming week and that actual weather data is measured accurately, ideally making use of an on-farm weather station.

Irrigation systems

The parameters of the irrigation system, via input data, should be taken into consideration in order for the software to adjust to the following: The limitations of your irrigation system, different soil types, unique environmental conditions and plant specific requirements.

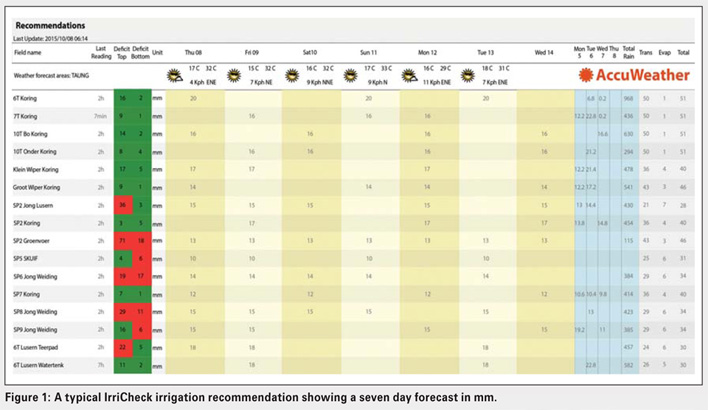

Recommendations

Recommendations should be live and in real-time (data should automatically be sent to the software) and in practical units, like millimetres, cubic meters or hours and minutes, and should be provided at least a week in advance. This allows the producer to make quick decisions and plan ahead, for instance, ordering water at least a week in advance. In addition, actual irrigation should be measured and checked against the recommendations in order to identify problems or check soil probe calibrations.

Recommendations should also be available on mobile applications for easy access – anywhere, anytime. Not all technologies are able to do this and producers should be aware and educate themselves on the different systems that are available.

While most software systems show changes in soil moisture content, this is just one of the elements required to schedule accurately. It is important that the software system implements a holistic approach by taking into consideration all the factors and data and not just single aspects.

PulseTM is one of the latest irrigation software systems based on this holistic approach. It provides real-time, live recommendations; taking into account and analysing all the required factors and data above. It has been in development since 1994 (Bertus van der Westhuizen [MSc Agric]) and is proudly South African.

Irrigation scheduling and load shedding

Producers who employ this technology (providing their recommendations are live and in real-time for at least a week in advance) will be able to compare this to the load shedding schedules to ensure that they are able to apply the required irrigation amounts when necessary or to manually adjust this, in which case the system will automatically readjust in real-time.

Irrigation scheduling and electricity costs

South African producers who have employed basic irrigation scheduling systems have experienced reduced pumping hours by as much as 15% as opposed to their traditional methods with accompanying savings in water and electricity costs, as well as much better utilisation of nutrients. Van Zyl is proud to say that their clients have achieved up to 30% in electricity savings by using their Pulse system.

“In addition to the above savings, plants in general react significantly better to these favourable, healthy soil conditions, particularly oxygen rich soils with better microbial activity and less leaching of nutrients. Under these conditions, yields, but even more so quality is generally increased and what better way to handle rising costs than by increasing yields?” Van Zyl closes.

With all the relevant data being collected and analysed, producers are continuously able to improve on their practices and ultimately become more and more sustainable.

Publication: November 2015

Section: Focus on