The accurate quality assessment of wheat and flour plays a fundamental role in determining its suitability for milling and baking applications. Different analyses provide insight into different quality aspects that describe the quality of this commodity, however, using test results in combination can contribute to an overall accurate quality assessment.

For this reason, between 1997 and 1999, a research project was conducted by ARC-Small Grains to evaluate the milling and baking worth of South African bread wheat cultivars. This was done in collaboration with representatives from the milling and baking industries and funded by the Winter Cereal Trust.

The research aimed to assess the milling and baking worth of South African bread wheat cultivars through a scientific and selection-index approach, considering both genetic and environmental factors. Three key production regions, namely summer-rainfall dryland winter wheat, winter-rainfall dryland spring wheat, and irrigated spring wheat were included and a mathematical model was utilised to compare and evaluate the qualities of different cultivars.

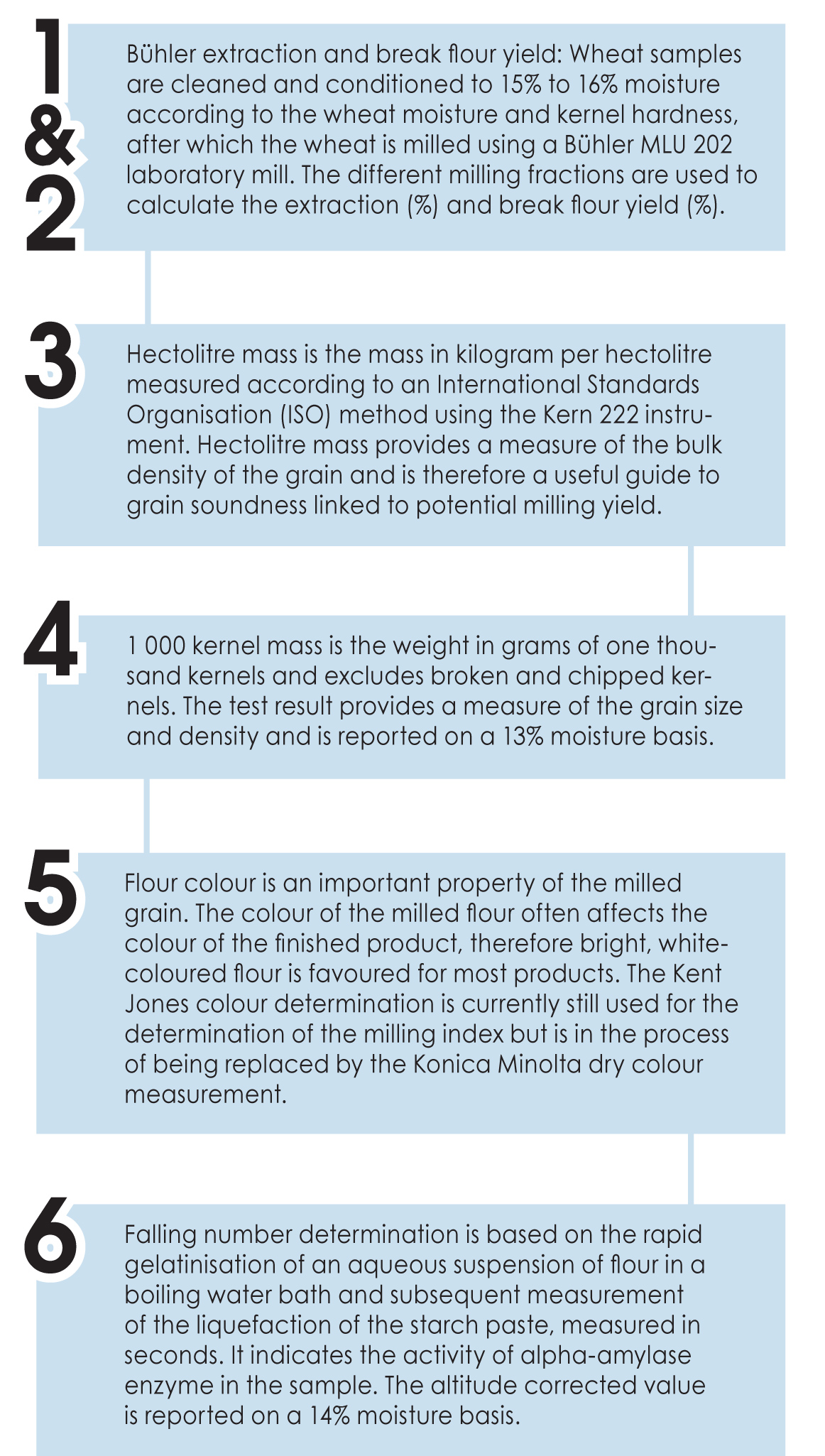

For the calculation of the milling worth values, six measurable factors contributing to the milling worth were selected. These factors are discussed in more detail below:

The baking worth calculation for wheat flour includes six characteristics, used to assess the overall quality and suitability of wheat flour for bread making:

- Loaf volume is determined using an industry-accepted 100 g optimised bread-making method. This 100 g baking test evaluation does not provide an indication of the baking quality of the flour per se but refers to the relationship between the protein content and the bread volume.

- Flour protein is measured using the Dumas combustion analysis technique, combusting the flour sample at high temperature in pure oxygen into different components. The nitrogen is isolated, detected and converted to equivalent protein by multiplication with a factor of 5,7.

- Farino water absorption: The farinograph measures the resistance of dough to mixing, which is expressed as consistency. The water absorption is the amount of water required for the dough to reach the required consistency. The amount of water added to the flour is then expressed as a percentage of the flour mass and reported on a 14% moisture basis.

- Alveo P/L: The alveograph measures the resistance of dough to stretching, expressed as stability (P = mm x 1,1) of the dough. Distensibility (L) provides an indication of the extensibility (in mm) of the dough. The P/L value is an approximate indication of the shape of the curve that combines the stability and the distensibility. Alveo strength is an indication of the strength of the dough and is expressed in square centimetres (cm2).

- Mixo development time: An industry-accepted method using the mixograph is used to determine the peak time. This is the time measured in minutes that dough requires to reach its maximum consistency or the first indication of dough weakening.

- The mathematical formulae that were developed for milling and baking worth enable the differentiation between good-quality and poor-quality wheat, irrespective of genotype and origin. Different quality characteristics, derived from selected laboratory results, can be used collectively to compare different bread wheat samples and enable an overall quality assessment.

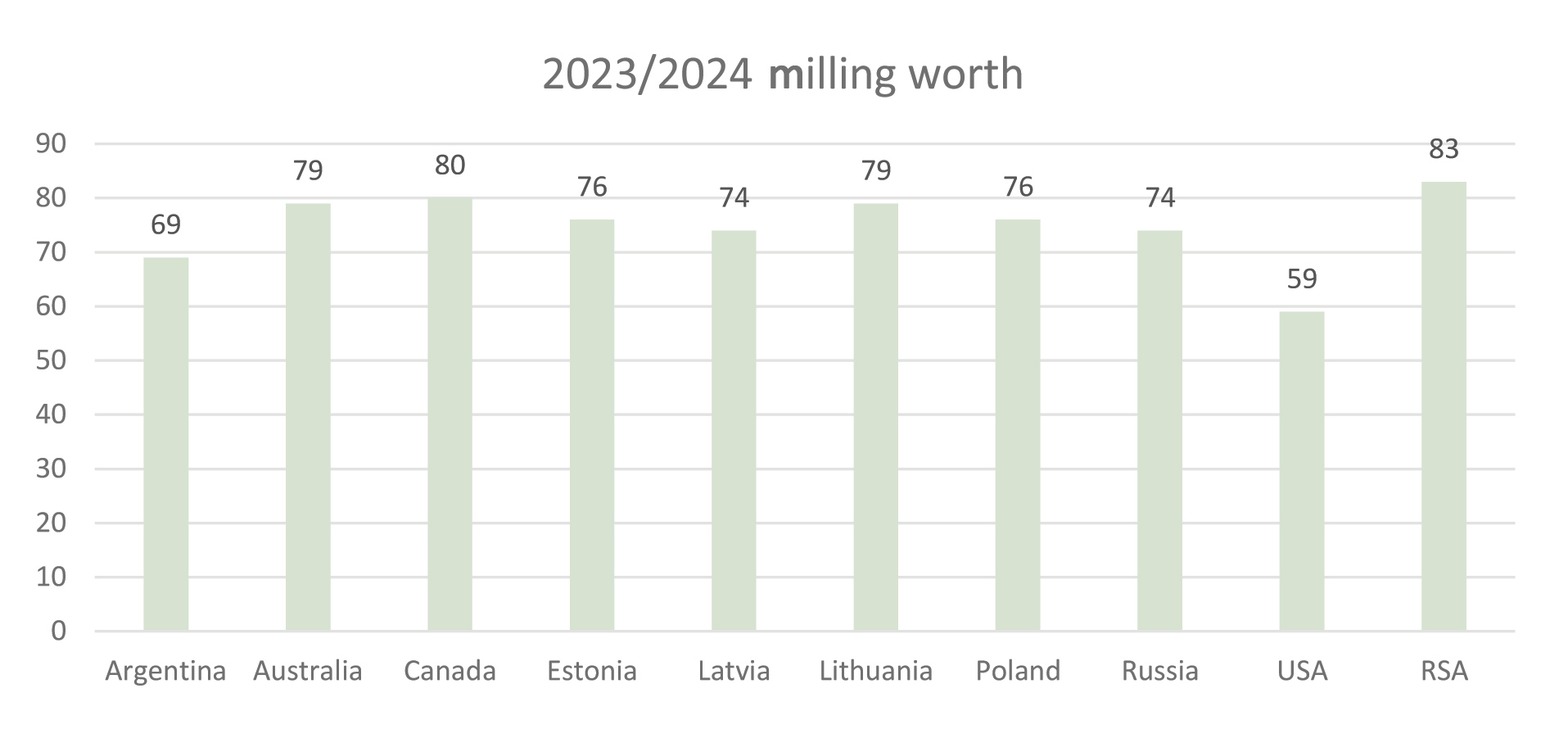

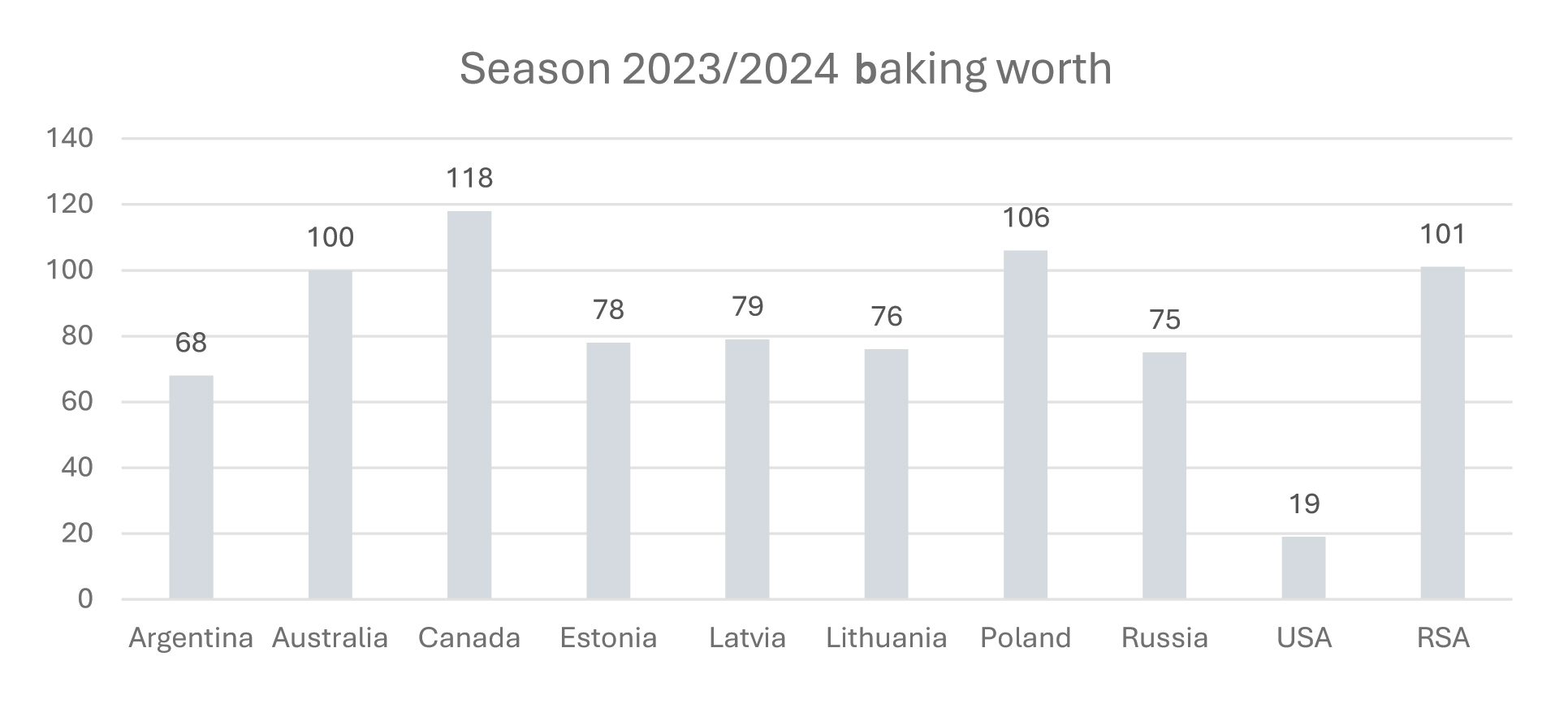

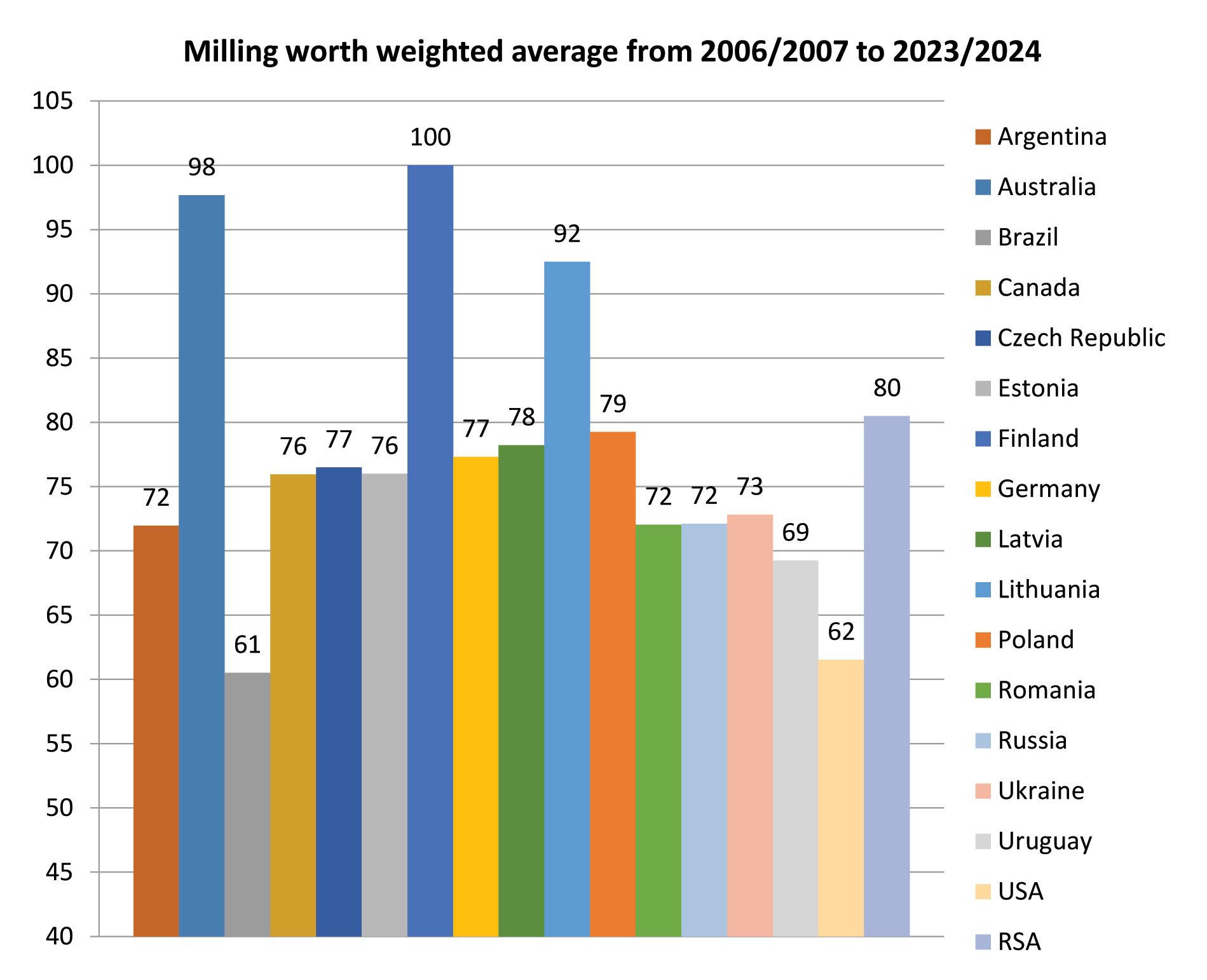

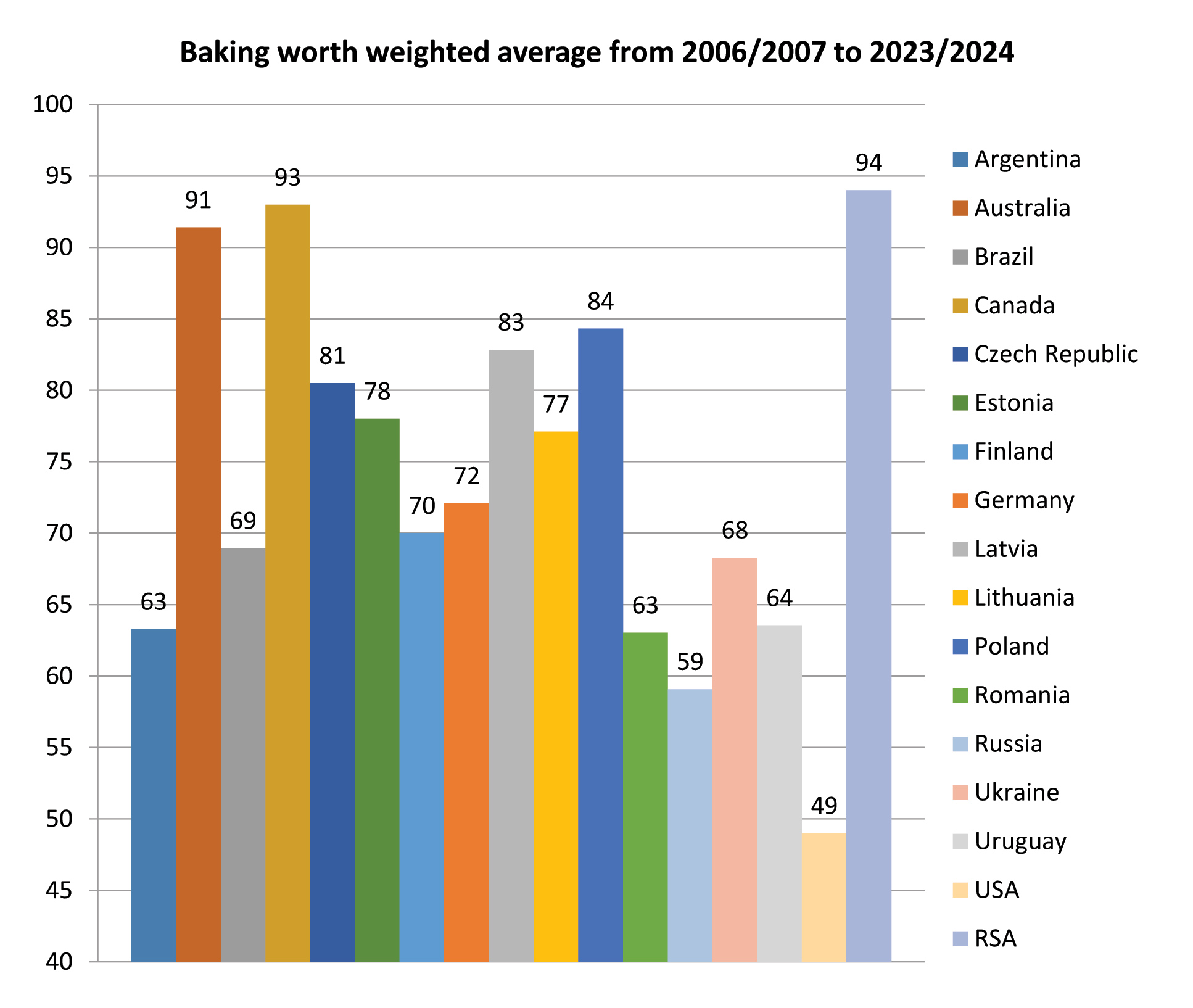

The South African Grain Laboratories (SAGL) has been conducting annual crop quality surveys on locally produced wheat since 1998. The analyses included in these surveys incorporate the required characteristics to determine the milling and baking worth of the wheat. Since the 2003/2004 season, imported wheat quality has been included in the annual surveys, applying the same scope of analyses to evaluate the quality of wheat imported and processed in South Africa. Availability of long-term quality data provides an excellent opportunity to compare the quality of locally produced wheat with that of imported wheat.

As agreed between the SAGL and the Department of Agriculture, import samples of shipments are collected by the inspectors of the department in the different ports and submitted to the laboratory. On completion of every season’s quality analyses, the milling and baking worth values can be updated to provide a measure to compare the quality of locally produced wheat with that of the imported wheat per season.

Figure 1 to 4 provide more information on the format in which this data are presented for comparison purposes.