Michael Petersen,

Michael Petersen, retired lead agronomist, Orthman Manufacturing

Root development and elongation are vital for crop production. The primary roles of healthy roots are to acquire water and nutrients, help regulate temperature, and anchor the plant. Secondarily, roots store photosynthates, synthesise growth regulators, and help distribute metabolic fluids to the plant above ground.

Compaction can limit root growth, therefore hindering crop production. Because most compaction is introduced by humans, agricultural producers must manage compaction in order to maximise production. This article will explain a research trial conducted at the Orthman research farm in the central United States that focussed on reducing compaction by utilising an 8RX four-track tractor rather than an 8R fully dualled tractor.

Compaction trial

The Orthman team partnered with a local John Deere dealer, AKRS Equipment, to determine the difference in compaction between an 8R tractor with full duals and an 8RX tractor, while using the same equipment in the same field. To complete this trial setup, using the 8RX tractor, 36 rows were strip-tilled with the 12-row 1tRIPr® and 32 rows were planted with the 16-row ExactEmerge planter. This was repeated using the 8R tractor. 16 rows were selected with the same direction of travel to use for the trial area.

They utilised the Spectrum Technologies SC-900 constant reading digital penetrometer to collect soil resistance data across the 16 rows of planted maize from the surface to 35,56 cm of depth in 19,05 cm increments on both ends and the centre of each pass. Additionally, 16 rows were individually hand harvested for 5,31 m at both ends and at the centre of the plot to determine the effect on yield by row. The maize was then harvested with an 8-row head and weighed to measure yield across the plot that was 378,6 m long and 0,23 ha.

Note: psi = pounds per square inch

Note: psi = pounds per square inch

Compaction trial results and discussion

Compaction trial results and discussion

When the penetrometer data were evaluated, the rows with wheel tracks or tracks from the 8RX could be identified. The difference: The compaction installed by the wheel tractor was deeper and more intense than that of the track tractor. Although the 8RX weighed 6 564 kg more than the 8R tractor, the tracks distributed the weight more effectively resulting in less compaction. It was also noticed that compaction was the most intense on the ends of the field where the strip-till and planter were starting and stopping. The differences in the centre of the 378,6 m length of planting were not as dramatic as the ends of the passes.

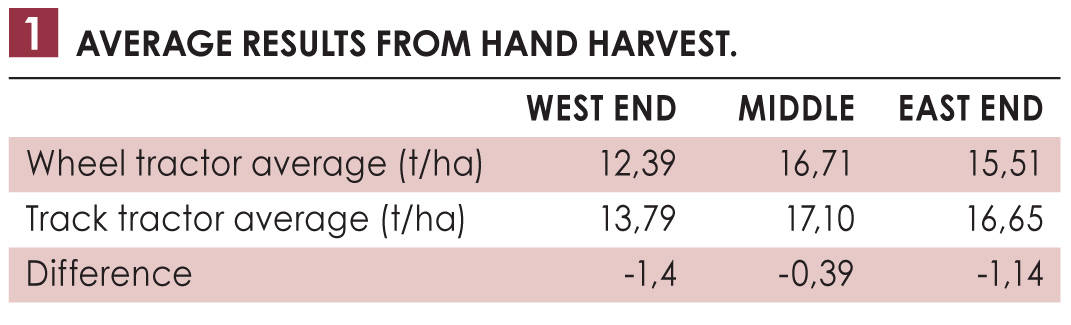

One week prior to harvest, ears from each of 16 rows were hand harvested for 5,31 m. The ears collected from each of the rows were weighed and an average moisture was measured. Using the ear weights, the yield was then estimated. This was repeated three times, once on each end of the passes and once in the centre of the passes. The west end was the end that the tractor started on for both the wheel tractor and the track tractor. The lowest yields were observed on the west end due to the load that the tractors were carrying as they started into the pass. There were less yield differences on the east end; and the least yield differences and highest yields in the centre. This was exactly as expected. However, it was surprising to see how low the yields were on the west end – that end may have been affected by a mid-season storm.

Similarly, a decreased yield on the east end of the field was observed as the tractor would slow and start loading the weight onto the tractor. The ends exhibited larger differences between the two tractors. The middle still showed a difference and it was predicted that the wheel tractor pass would yield 0,38 t/ha less than the track tractor in that area. Every eight rows of each of the tractors were harvested.

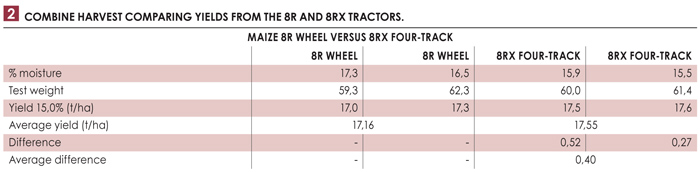

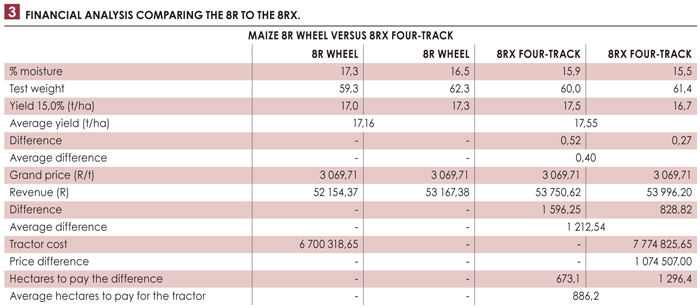

Interestingly enough, when the trials harvested with the combine were weighed, there was an average difference of 0,40 t/ha between the tractors. The wheel tractor averaged 17,16 t/ha, while the track tractor averaged 17,55 t/ha. This difference would result in an average revenue increase of R1 212,54 with the 8RX over the 8R. Estimating the cost of the 8R at R6 700 318,65 and the 8RX at R7 774 825,65, there is a price difference of R1 074 507,00 between the tractors.

Based off of this study that demonstrated an increase in yield of 0,40 t/ha producing an additional revenue of R1 212,54/ha, it can be estimated that the price difference between the tractors could be made up with 886,2 ha. The two replications ranged from 673,1 ha to 1 296,4 ha. The team is confident that this data can help producers think differently about equipment options.

The team would further like to determine how far from the start and stop the larger yield differences occur in order to calculate a more in-depth estimation of yield differences across entire fields.

This data are similar to data reviewed from prior trials and give another opportunity to observe the effects of compaction on root development and yield.