AB InBev

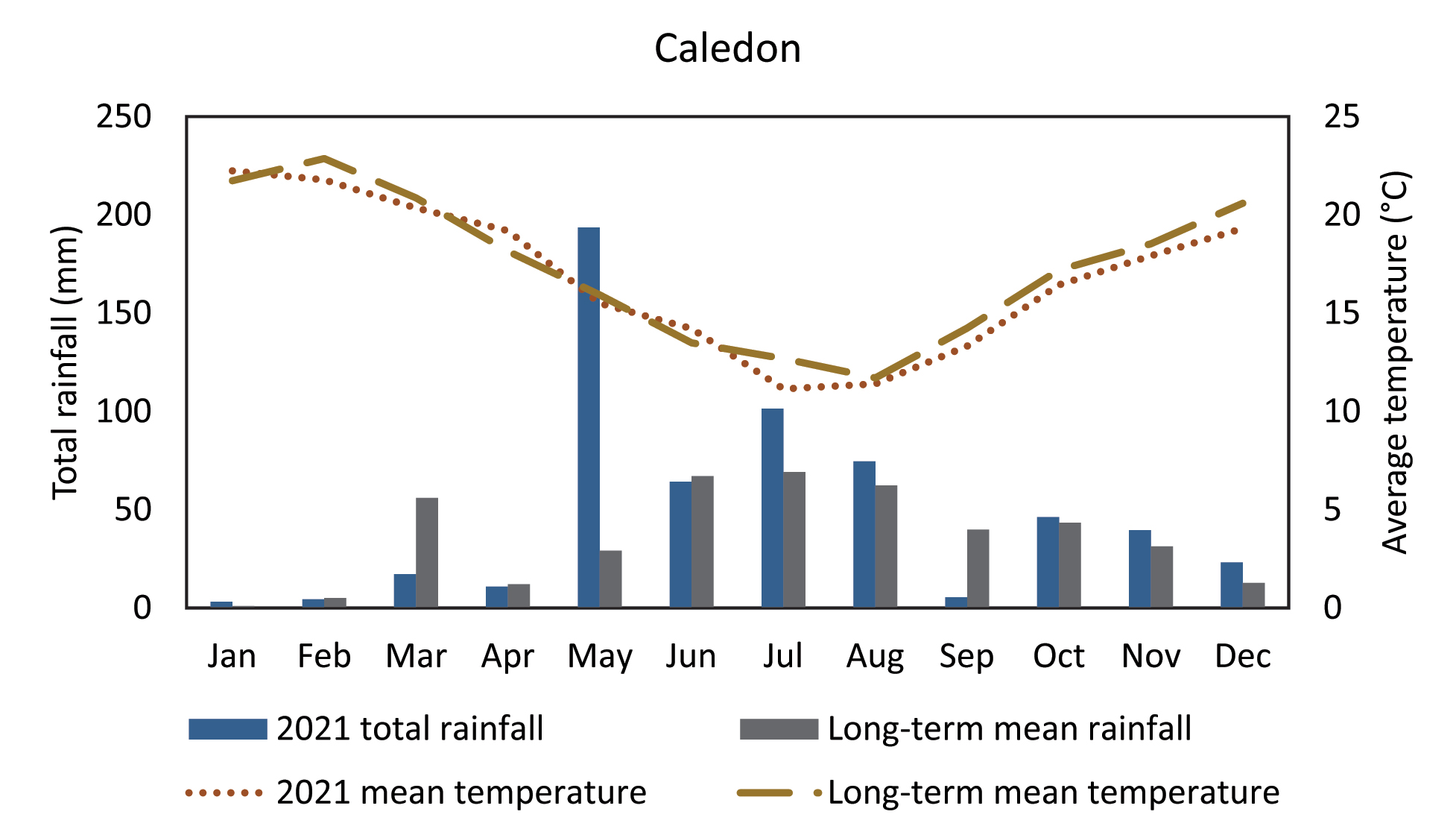

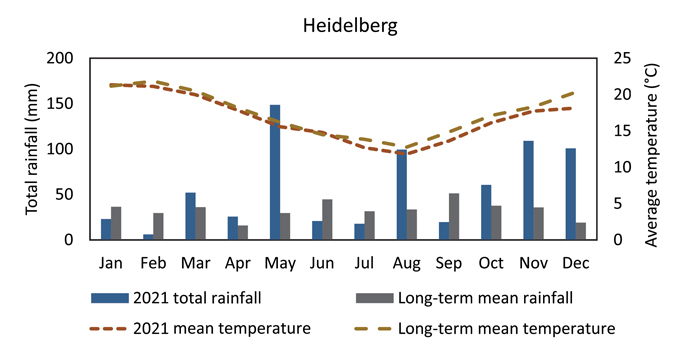

Low barley grain nitrogen content was commonly observed during the 2021 harvest. The low grain nitrogen content at harvest was a result of excessive rainfall (Graph 1 and Graph 2) early in the growing season, with consequent waterlogged conditions which restricted root growth, led to nutrient loss as a result of leaching, and decreased nitrogen uptake.

Furthermore, minimum temperatures from June to August were much lower compared to the long-term minimum temperatures for these months (Graph 1 and Graph 2), further promoting low grain nitrogen content during this yield-determining crop phase of the barley plant.

Inconsistency in grain nitrogen content is often attributed to unpredictable differences in nitrogen mineralisation in the soil which affects the nitrogen supply of the soil. Soil nitrogen mineralisation is determined by the soil organic matter content, soil nitrogen content and physical factors influencing the nitrogen mineralisation process, such as soil water content and temperature acting on micro-organism activity. Temperature in particular affects the rate of nitrogen mineralisation in the soil and thereby the grain nitrogen content. Under waterlogged, dry and cool soil conditions mineralisation rates are known to be slower, thereby contributing to low grain nitrogen content.

What determines the final grain nitrogen content of barley?

Grain nitrogen content is a function of nitrogen uptake from the soil, nitrogen assimilation in the plant and nitrogen redistribution from the vegetative parts of the plant to the grain. The combination of the aforementioned parameters together with the crop yield potential determine the final grain nitrogen content at harvest. The nitrogen content of barley is a characteristic that is not only environmentally, but also genetically, influenced. Certain cultivars produce lower grain nitrogen content despite higher nitrogen fertilisation. Such a characteristic of a cultivar would be beneficial as it is not only high nitrogen fertilisation that increases the nitrogen levels in the grain, but also uncontrollable factors such as drought and heat stress during the grain-filling period and the nitrogen supply capacity of the soil.

Nitrogen fertilisation effect on barley grain nitrogen content

Nitrogen fertiliser applications are known to greatly influence grain nitrogen content. A high grain nitrogen content in barley is usually a result of a large uptake or redistribution of nitrogen late in the season due to high or late nitrogen fertiliser application. Where fertiliser management practices are aimed at low nitrogen malting barley, reduced nitrogen fertiliser rates are required. It is therefore important to match the nitrogen rate with the desired yield and quality targets.

Future nitrogen fertiliser research by AB InBev

AB InBev plans to launch a trial in 2022 in collaboration with Stellenbosch University and Yara that will focus on the development of nitrogen fertiliser guidelines under conservation agriculture management systems. The trials will be aimed at predicting the most efficient nitrogen rate and nitrogen source for a specific area according to the inherent soil (clayey or sandy), climate (dry or wet), and rainfall (high or low) characteristics in order to ensure optimum barley yield and malting quality.

Furthermore, the trials will also investigate the influence of foliar nitrogen applied at different crop growth stages as well as the effect of applying all fertiliser nitrogen at planting. Research results will be used to communicate barley nitrogen fertiliser strategies to all barley producers and the industry after completion of the trials.

Why is it important to adhere to grain nitrogen content specifications?

Accurate malting is the essence of accurate brewing. Therefore, it is important that the grain nitrogen levels of barley adhere to malting specifications and are as homogenous as possible to ensure even barley kernel germination and processing. A delivery or brew containing uneven grain nitrogen can cause uneven processing of the malt, with consequent problems in the brewery. Therefore, maltsters set certain quality standards for malting barley to ensure that the end product is produced in the most economical way possible.

Barley with extensively high or low nitrogen content cannot produce malt of the required quality for brewing purposes. The sliding scale according to which the price of barley is determined, is based on a base price onto which premiums are added for certain nitrogen levels in the grain. Although grain with a nitrogen content of between 1,5% and 2,0% is accepted as malting barley, the premium is only payable on grain with a nitrogen content of between 1,61% and 1,94% on specific varieties.

An inverse relationship exists between grain nitrogen content and malt extract. Lower grain nitrogen results in higher malt extract, resulting in a lower malt demand by the brewer in order to produce the same amount of beer. Amylase enzyme levels, the enzymes responsible for converting starch to fermentable sugars in mashing (the process of combining malted barley with supplementary grains and water and heating the mixture), also decrease with a decrease in grain nitrogen content. Malt with too low amylase levels may convert too slowly in the brewery, making it difficult to handle the malt. In contrast, high grain nitrogen content malt may contain too high enzyme levels, decreasing the duration of the conversion times in the mashing process.

Why is grain nitrogen content so important?

About 40% of the total kernel nitrogen content is converted to soluble proteins during malting. Soluble proteins, which include general proteins, peptides and amino acids, are important for yeast growth in fermentation and also in malt or beer colour development. Lower nitrogen containing malt yields lower soluble protein which can cause fermentation issues for the brewer. It can cause less colour development in the malt and beer and can also result in poor fermentation. Very high grain nitrogen may yield high soluble protein, resulting in too much colour development and a haze in packaged beer.

The AB InBev agricultural team proactively supports the barley value chain

Thanks to the AB InBev agricultural team, strategies to effectively manage low total grain nitrogen levels before harvest were developed and implemented from 2020. Preharvest samples are taken randomly in all barley production areas at a seed moisture content of >16%. The motive behind the sampling initiative is to give both the grower and storage partner an indication of moisture and total grain nitrogen content before harvest, thereby preventing any risks at first point of delivery.

AB InBev believes in a long-term sustainable barley industry and will remain committed and invested in the entire barley value chain from seed to sip.