director: CFAM Technolo-gies (Pty) Ltd, professor in Mechanical Engineering, North-West University, Potchefstroom

According to the World Health Organisation (WHO), more than 260 million people in sub-Saharan Africa (SSA) are undernourished. This represents 21% of the population in this region. There is also a rising incidence of non-communicable diseases as diets shift with incomes and urbanisation.

In 2019 the total consumption of grains in SSA was 140 million metric tons. According to the Food and Agriculture Organization of the United Nations (FAO), maize, rice, wheat, and sorghum equate to 89% of total grains consumed. These grains contribute to about 45% of average daily caloric intake in SSA. Since these grains have generally low levels of protein, general diets in the SSA region usually lack sufficient proteins as macronutrients.

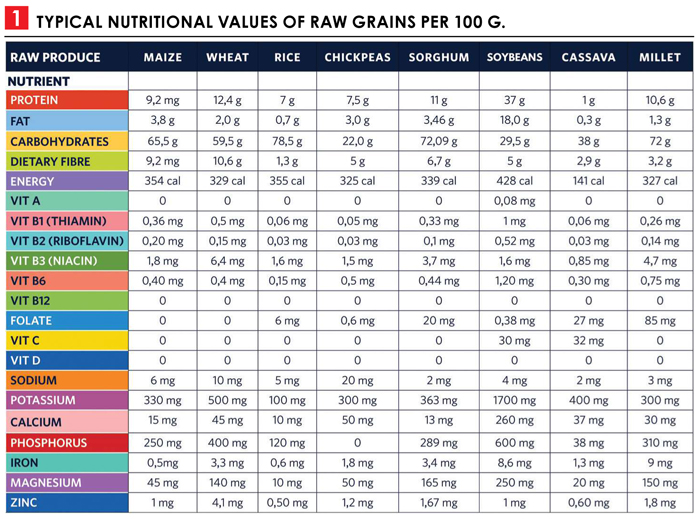

Nutritional value of grains

Table 1 gives typical nutritional values of raw grains per 100 g. Nutrients are compounds in food that are essential to life and health. They provide energy, the building blocks for repair and growth as well as substances necessary to regulate the chemical processes in the human body. Chickpeas and soy are better sources of protein. Multigrain products that use two or more grains therefore provide more nutritionally balanced foods.

Micronutrients, which include vitamins and minerals, can be added through fortification. Most countries therefore introduced regulations that make fortification of raw meal and flours mandatory. However, it is important to note that cooking of the meal or flour destroys most vitamins from grains and pulses. Traditional starch-based meals in the region, such as pap, ugali, chapati, etc. therefore lack sufficient levels of vitamins after being cooked.

Micronutrients, which include vitamins and minerals, can be added through fortification. Most countries therefore introduced regulations that make fortification of raw meal and flours mandatory. However, it is important to note that cooking of the meal or flour destroys most vitamins from grains and pulses. Traditional starch-based meals in the region, such as pap, ugali, chapati, etc. therefore lack sufficient levels of vitamins after being cooked.

According to the WHO, micronutrient malnutrition affects millions of people in Africa. Micronutrient malnutrition accounts for 7% of the global burden of diseases. Iron and vitamin A deficiencies contribute to 1,5 million deaths per year.

New studies have found that whole grains reduce the risk of cancer, diabetes, infectious disease and help to reduce the risk for cardiovascular disease. Many countries therefore suggest 33% to 50% of grain servings should be wholegrain. The USA and Canada recommend that at least 50% of grain products consumed each day should be wholegrain, while the Swiss Society for Nutrition recommends that 67% of daily recommended starch servings should be wholegrain.

It is becoming generally accepted that good nutrition leads to optimal brain development, great health and ultimately thriving communities. The provision of adequate nutrition is therefore seen as central in uplifting local and regional communities and to develop their ability to uplift themselves.

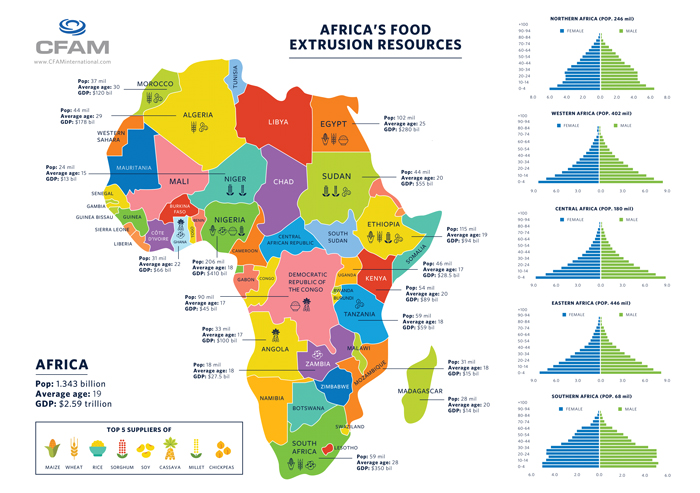

Figure 3 shows the different food extrusion resources of Africa. It includes the following:

- Top five supplying countries of maize, wheat, rice, sorghum, soy, cassava, millet and chickpeas.

- Populations of the main countries.

- Average age of the countries.

- Annual gross domestic product (GDP) of the countries.

- Male and female population age distribution.

Africa has a total population of 1,343 billion, making it the second most populated continent. The population is expected to increase to 2 billion by 2050. An ever-increasing number of children is suffering from malnutrition. The average population in Africa is 19 years of age, meaning that more than 50% of the population is not part of the working population. Urbanisation will lead to 30% growth of cities’ population by 2030 according to the World Bank. 90% of the world’s urbanisation will be in Africa.

COVID also had a severe negative impact on the local economies of Africa and SSA. It disrupted the food supply chains and forced millions of people and children into poverty that caused hunger, malnutrition, job losses and hardship.

New opportunities emerge

As signs are here that the end of the pandemic is moving closer, opportunities are starting to emerge for the SSA region and Africa. Africa has fertile agricultural land, water, and sufficient sun to rebuild itself post COVID-19. To succeed regional and local economic activities need to be created and established to create sustainable local supply of safe food, energy, and water.

The opportunity therefore exists to build strong value chains from the farm gate to the end consumer that supply safe affordable nutritious foods made from locally produced agricultural products.

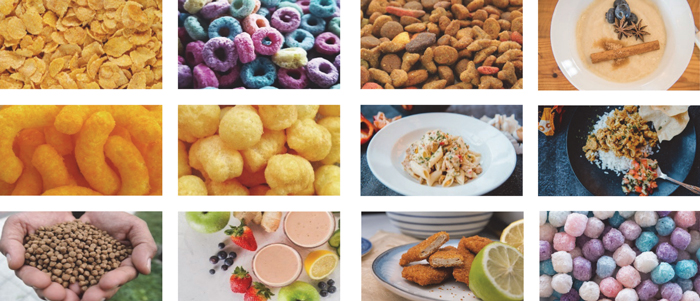

Humans cannot eat raw grains and pulses. It therefore must be cooked, either in a processing facility or at home before it is consumed. Extrusion has become a popular technology for processing and cooking of grains and pulses. It is a continuous high pressure and high temperature cooking process that is used to produce ready-to-eat products, such as instant porridges, breakfast cereals, puffed snacks, pet foods and aqua feeds. The latest developments focussed on meat analogues from plant-based proteins.

Extrusion plants are central to the establishment of complete value chains between the farm gate and the end consumer. These plants form the heart of the value chain and perform functions that cannot be done by humans. Extrusion is therefore a technology that – contrary to general belief – creates jobs and does not take them away! The establishment of strong value chains also creates a market for local producers, thus strengthening the local economy.

Benefits of using extrusion to cook grains and pulses include the following:

- Enable the production of safe, affordable nutritious foods.

- Local beneficiation of local produce.

- Localised technology – from Africa for Africa.

- Create value chains from farm gate to end consumer.

- Local economic development.

- Job creation.

- It is energy efficient.

- Continuous cooking process.

- No waste streams.

- Mitigate climate change – shifting towards more plant-based diets.

Figure 1 shows samples of extruded products. All products have been produced on the same machine that were reconfigured for the different products.

The latest advancements in extruders and specifically twin-screw extruders have been central in the development of modern meatless meat analogue products. With twin-screw extruders it is now possible to produce meat analogues with the same attributes as real meat. When prepared in a dish, it is often impossible to distinguish between the meat analogue and the real meat product (Figure 2).

Proper implementation of these value chains therefore assists in creating jobs and alleviating poverty, while leading to local economic growth, local beneficiation of products, regional revitalisation, food security and supply of nutritional foods.

CFAM Technologies is a South African company that was established in 2007 with the aim to commercialise twin-screw extruders for Africa and the developing world. It is a spin-off company of the North-West University (NWU) and the only manufacturer of twin-screw food extruders in Africa and the Southern Hemisphere.

CFAM’s extrusion equipment is backed by more than 20 years of research and innovation at the Faculty of Engineering at the NWU in Potchefstroom. It focussed its research on developing safe, nutritious, affordable foods from locally produced agricultural products. CFAM is well positioned to assist the South African, SSA and African agricultural sector in developing new products to beneficiate locally produced agricultural products.

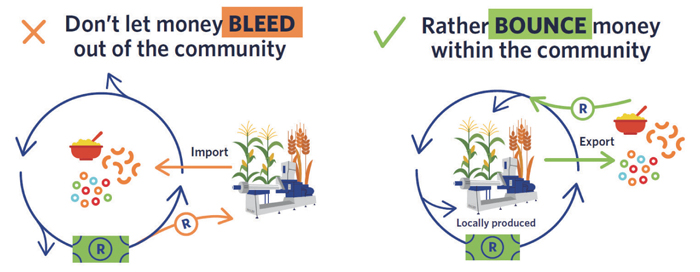

Figure 4 illustrates how extrusion can assist in creating local economic development.

Building the local economy

When a community is dependent on imported produce and products, money bleeds out of the community, resulting in an unstable economy. By creating a circular economy, money flows between different sectors. By exporting products, money flows into the circular economy, thus strengthening the local economy.

The production capacities of small and medium-sized commercially viable extrusion plants typically vary from 300 kg per hour upwards to 6 tons to 10 tons per hour. Larger plants have capacities of up to 25 tons per hour and more. Small and medium-sized extrusion plants are ideally suited for regional plants that assist with local economic development.

An extrusion plant creates a market for the local farmers’ agricultural produce and forms the heart of the value chain between the farmer and the end consumers. The cost for complete small extrusion plants starts around R6 million. Mid-sized extrusion plants cost between R15 million to R20 million with medium-sized plants around R30 million.

Extrusion plants generally generate annual revenues that exceed the setup cost of the plant. Such plants add significant value to the raw materials that are being processed. Under normal business conditions the payback of an extrusion plant is about three years. Under favourable business conditions it can be less than two years!

For more information contact Prof LJ Grobler at LJ@cfam.co.za.