Dr Hendrik Smith, ASSET Research

Mary Maluleke, ASSET Research

Prof James Blignaut, ASSET Research; Restore Africa Fund Manager; Stellenbosch University, School for Public Leader-ship; South African Envi-ronmental Observation Network (SAEON)

Nic van Schalkwyk, Restore Africa

Fund Manager

Anika de Beer,

Restore Africa

Fund Manager

Jaap Knot,

ASSET Research

Gerrie Trytsman,

ASSET Research

Crop producers are faced with the combined consequences of severe increases in input costs (even over a prolonged period of time), the negative impact of soil erosion on the productive capacity of a farm, climate change and being price takers and not price makers.

This implies that the options for the producer to hedge him/herself against financial distress, even catastrophe, are limited. Moreover, primary agriculture as a sector, more than any other, must consider the long term with more attention and seriousness given the nature-based character of its product, the contribution of its product to the welfare and well-being of the country, and the impact of nature – sun, wind, rain, soil and time – on its production.

Selecting a production system for a farm is therefore a matter of strategic concern for the producer, the industry and the country. In the wake of the various production challenges and profit leakages, while simultaneously needing to maintain competitiveness and ensure sufficient production for the growing population, something must change.

Producers need a solution that will not only ensure financial viability in the long run, thereby enabling their grandchildren to continue the legacy of service to the nation, but also one that will help them to adapt to the challenges associated with a changing environment. Several studies, both locally and abroad, indicate that regenerative agriculture provides such a solution. The question is how this system compares financially to other, more conventional, production systems.

The case of the Mpumalanga grain production area

To answer this, a model was developed based on data from three fully statistical, on-farm trials running in the Mpumalanga Highveld region, with two of the sites near Kinross and the other one near Standerton. These trials are implemented under the CA Farmer Innovation Programme, with funding by the Maize Trust and coordination by ASSET Research.

In this model, a 1 000 ha farm is assumed, comprising six croplands of 100 ha each and a grazing area of 400 ha, and using a business-as-usual conventional tillage system (CT). The question arises whether there are financial benefits in converting this operation to either a no-tillage system (NT), or a fully integrated crop-livestock regenerative conservation agriculture (CA) system.

CT employs various primary and secondary tillage practices with grazing taking place on the grazing lands, while NT uses no-till planters, with livestock grazing the same as under CT. CA also uses no-tillage practices, but employs a far more complex crop rotation system, integrating it with cover crops which are used for the livestock. The latter is thus used intensively in both the grazing area and the croplands.

In addition to the primary data collected on the farms, data from Grain SA for operational costs and from VKB for capital costs, were used. The model analysed and compared the costs (operating and capital) and benefits (income) of the three production systems, while keeping all macro assumptions regarding the prices of maize and soybeans, unit costs of animals and costs and revenue inflation, uniform for all the systems. The estimated yield quantities and the underlying crop rotation systems were modelled as follows:

- A simple maize and soybean rotation yielding 7 t/ha and 2 t/ha respectively with livestock external for both CT and NT systems, and

- a fully integrated CA crop-livestock system with maize and soybean rotations with the same yield, but with intercropping yielding an additional 2 t/ha of biomass, rotated (or interrupted) with one season of annual mixed summer cover crops yielding 10 t/ha and winter cover crops yielding 2 t/ha.

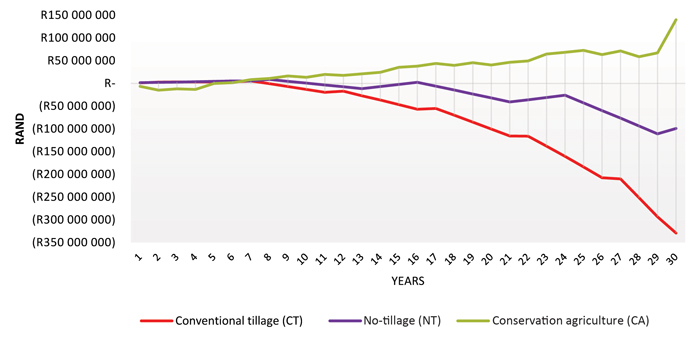

Converting a full production system from CT to NT or CA does imply the acquisition of new equipment, such as no-till planters, and in the case of CA, additional livestock. There are, however, considerable savings when it comes to the input costs, notably that of fertilisers, herbicides, pesticides and fuel. As a result, the dynamics over time of the CT, NT and CA systems differ, as indicated in Graph 1 that shows the cumulative free cash flow (CFCF) over a 30-year period.

Results

Depending on how the new acquisitions are financed, there seems to be a moderate reduction in the CFCF for NT and CA in the first few years, whereafter CA outperforms the other two by a significant amount. The CFCF for CT in year 10 is estimated to be -R13 million, with that of NT at R500 000 and CA at R13,5 million. This changes to -R100 million in year 20 for CT, -R32 million for NT and R40 million for CA. In year 30, the CFCF for CT is estimated to be a staggering -R330 million, with NT at -R100 million and CA at R139 million. The main reasons for the improved performance of the CA system are the combined impact of the reduced input costs and the value of the livestock.

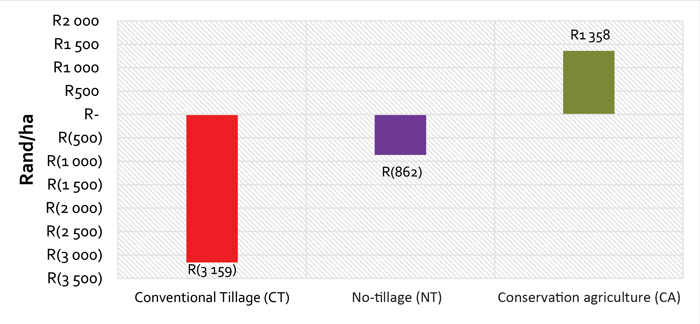

The net result of these dynamics over time is that the average cash flow (ACF) per hectare in real terms at the conclusion of year 30 for CT is declining to -R3 159/ha, and that of NT to -R862/ha, while that of CA is increasing to R1 358/ha (Graph 2). The implications of these results from a food security and system resilience perspective are enormous. The financial sector needs to invest in CA and assist producers to make the required transition.

Considering the growing financial case for and various environmental benefits of CA, producers are advised to convert from CT systems to CA systems. This conversion might take place incrementally from CT to more climate-smart NT systems and over time adapt to fully integrated CA systems.

The conversion will make a significant contribution to a much more food-secure country. Food security is defined by the Food and Agriculture Organisation of the United Nations (FAO) as ‘when all people, at all times, have physical, social and economic access to sufficient, safe and nutritious food that meets their dietary needs and food preferences for an active and healthy life’.

The case of the Maluti grain production area

Another model was developed based on data from two fully statistical, on-farm trials running in the Ficksburg and Marquard areas in the Maluti Eastern Free State region. These trials are also implemented under the CA Farmer Innovation Programme with funding by the Maize Trust and coordination by ASSET Research. In the model, a 1 000 ha farm is assumed, comprising three croplands of 100 ha each and a grazing area of 700 ha and farmed based on a business-as-usual CT system. CT employs various primary and secondary tillage practices with grazing taking place on the grazing lands, while NT uses no-till planters, while livestock grazing is the same as under CT. CA also uses no-tillage practices, but employs a far more complex crop rotation system, integrating it with cover crops used for livestock – with the latter thus employed intensively in both the grazing area and the croplands.

In addition to the primary data collected on the farms, data from Grain SA with respect to operational costs and from VKB for capital costs, were used. The model analysed and compared the costs (operating and capital) and benefits (income) of the three production systems, while keeping all macro assumptions regarding the prices of maize and soybeans, unit cost of animals, and costs and revenue inflation, uniform for all the systems. The estimated yield quantities and the underlying crop rotation systems were modelled as follows:

- A simple maize and soybean rotation yielding 5 t/ha and 1,8 t/ha respectively with livestock external for both CT and NT systems; and

- a fully integrated CA crop-livestock system with maize and soybean rotations with the same yield, but with intercropping yielding an additional 2 t/ha of biomass, which are rotated (or interrupted) with one season of annual mixed summer cover crops yielding 8 t/ha and winter cover crops yielding 2 t/ha.

Results

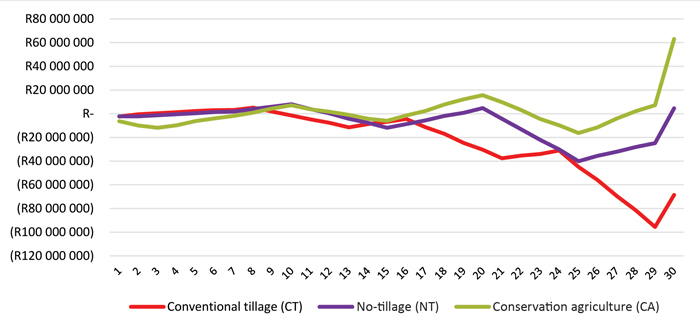

The CFCF (Graph 3) for CT in year 10 is estimated to be -R14,4 million, with that of NT at R8 million and CA at R7,2 million. This changes to -R30,4 million in year 20 for CT, to R4,8 million for NT and to R15,5 million for CA. In year 30, the CFCF for CT is estimated to be -R68,5 million, with NT at R4,6 million, while CA is expected to grow to R63 million. Although CA has periodic dips of negative CFCFs in the initial period due to the acquisition of implements and livestock (cattle), there are considerable reductions in input costs due to the reduced dependence on fertilisers, herbicides, pesticides, fuel, etc. This cost reduction has a significant positive impact on long-term profits relative to CT and NT.

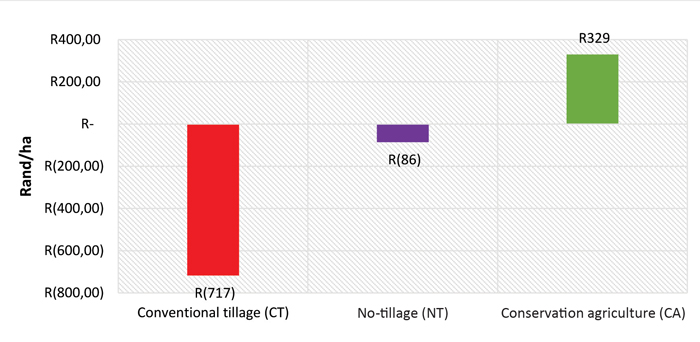

Over time the net result of these dynamics is that the ACF per hectare in real terms at the conclusion of year 30 for CT declines to -R717/ha, and that of NT to -R86/ha, while that of CA increases to R329/ha. This implies a net difference of R1 046/ha and R415/ha compared to the CT and NT options respectively (Graph 4).

These results have important implications for food security and system resilience. Producers must seriously consider the transition to more sustainable and regenerative options, but to do that the financial sector has to invest in CA and assist producers in making the required transition. To continue funding CT practices while being fully aware of the perils due to climate change and knowing that the cost of inputs will continue to rise, is unethical. In addition, such lending practices could be considered as reckless. To support the successful conversion to NT and CA is an investment in the future and will lead to a more food-secure South Africa.