In today’s industrial landscape, advanced technology and innovative solutions are essential to meet evolving demands. CFAM Technologies stands out as a leader in extrusion systems and turnkey solutions. With operations in 18 countries across Africa, Europe, Asia, and North America, CFAM is a significant contributor to advancements in food processing, animal feed production, and related industries.

Driving innovation in extrusion technology

CFAM Technologies, based in Potchefstroom, specialises in the design, manufacturing, and implementation of extrusion equipment and plants. The company has built a strong reputation for providing reliable and efficient solutions tailored to meet the specific needs of its clients. CFAM’s commitment to innovation, quality, and service excellence ensures that every project maximises efficiency and profitability, addressing the unique requirements of its diverse clientele.

The company offers a comprehensive suite of services, including custom design and manufacturing, technical training, and consultation. Additionally, its 24-hour maintenance and support services provide clients with the assurance of minimised downtime and optimised production processes. These elements collectively position CFAM as a trusted partner in the extrusion technology sector.

Applications of CFAM extrusion technology

CFAM’s extrusion systems find applications in various industries, where they add value to raw materials and facilitate the production of high-quality products. These applications span the following:

Pet food

The production of pet food through CFAM systems allows for precise customisation to include essential nutrients, vitamins, and minerals, catering to diverse dietary needs. The technology ensures consistent texture, shape, and size, delivering products suitable for all market segments, from economy to premium-grade options.

Aqua feeds

CFAM extrusion systems enable sustainable and efficient aqua feed production. The feeds are designed to reduce waste, with floating or slow-sinking options that minimise environmental impact. High digestibility ensures optimal nutrient absorption for aquatic species, supporting healthier growth. Furthermore, formulations can be tailored to meet the specific dietary needs of various aquatic organisms, including fish and shrimp.

Breakfast cereals

Breakfast cereals produced with CFAM technology meet consumer demands for convenience and nutrition. The equipment allows for the creation of diverse cereal products, including flakes, puffs, and clusters, with customisable shapes, flavours, and textures. The inclusion of whole grains and other health-focused ingredients ensures alignment with modern dietary trends.

Snack foods

CFAM extrusion technology supports the production of innovative snack foods with creative shapes and appealing flavours. These systems cater to the growing market for health-conscious snacks by enabling the manufacture of high-protein, low-fat options. The efficient production processes also ensure cost-effective operations, reducing waste and enhancing profitability.

Instant porridges

Instant porridges created using CFAM systems offer rapid preparation, enhanced nutritional value, and versatility in formulation. These porridges can be enriched with vitamins, minerals, and proteins, providing balanced nutrition for various demographics. CFAM’s technology accommodates diverse raw materials such as maize, sorghum, rice, and millet, allowing the production of multi-grain porridges.

Multi-grain porridges combine the nutritional benefits of different grains, offering improved fibre content, essential amino acids, and a range of vitamins and minerals. The inclusion of fortification further boosts the nutritional profile, addressing micronutrient deficiencies in target populations. These products can be tailored to meet the dietary needs of specific groups, such as infants, young children, athletes, or individuals with dietary restrictions.

CFAM’s systems also support the use of locally sourced raw materials, fostering economic growth in communities while providing cost-effective production solutions. By enabling customisation of formulations to align with cultural preferences and dietary guidelines, CFAM’s instant porridges address both nutritional and market demands.

Wholegrain products

CFAM’s technology plays a pivotal role in integrating whole grains into snacks, breakfast cereals, and instant porridges. Whole grains provide a range of economic and health benefits. Economically, using locally sourced whole grains reduces costs associated with imported refined grains and adds value to premium market segments. From a health perspective, whole grains are rich in fibre, vitamins, and minerals, supporting cardiovascular health, improving digestion, and aiding weight management. These benefits make wholegrain products appealing to a broad consumer base, including health-conscious individuals.

Incorporating whole grains into snacks and breakfast cereals offers a dual advantage of financial savings and enhanced health benefits. From a financial perspective, using whole grains can lead to cost efficiency. Whole grains, compared to refined grains, often have lower production costs due to fewer processing steps required to remove their nutritious components. This cost-effectiveness can positively impact manufacturers’ bottom lines while delivering better value to consumers.

From a health standpoint, the benefits of using whole grains are substantial. Whole grains are rich in dietary fibre, which aids digestion, promotes satiety, and helps manage weight. The complex carbohydrates found in whole grains release energy gradually, providing sustained fuel and preventing sharp spikes in blood sugar levels. Additionally, whole grains are abundant in vitamins (like B vitamins) and minerals (such as magnesium, iron, and zinc), supporting various bodily functions and overall well-being.

The high fibre content of whole grains contributes to heart health by lowering cholesterol levels and reducing the risk of cardiovascular diseases. Moreover, the antioxidants present in whole grains combat oxidative stress, potentially lowering the risk of chronic illnesses like diabetes, certain cancers, and inflammation-related conditions.

Choosing whole grains for snacks and breakfast cereals therefore translates to financial savings due to reduced processing costs. Simultaneously, these products offer health benefits through their rich fibre, nutrient, and antioxidant content, promoting digestive health, balanced energy release, and contributing to the prevention of various chronic diseases. This dual advantage appeals to both manufacturers and health-conscious consumers, aligning profitability with public well-being.

Turnkey extrusion plants

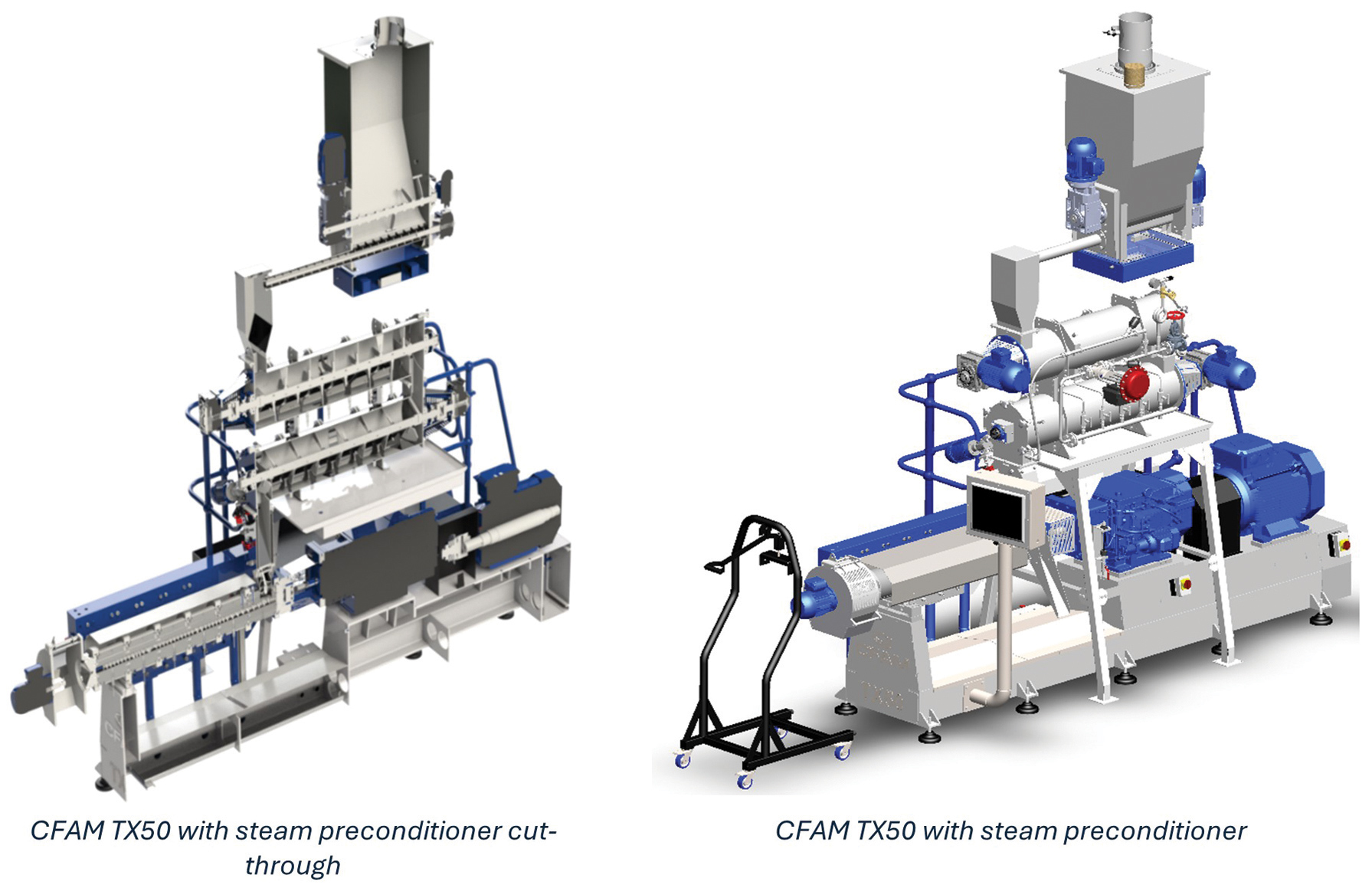

CFAM excels in providing turnkey extrusion plants, offering clients a seamless and integrated solution for their production needs. From raw material processing to finished product packaging, CFAM’s plants are designed to cover every step of the production process.

The company’s engineering team is renowned for its excellent design capabilities and ability to provide complete engineering, procurement, and construction (EPC) services. These turnkey plants are tailored to meet the specific needs of each client, ensuring scalability and adaptability to market demands. With advanced automation solutions, CFAM’s systems deliver superior operational efficiency and precise process control, reducing manual intervention and optimising productivity.

Durability and reliability are key features of CFAM’s extrusion plants, which are constructed using high-quality materials and precision engineering. By managing every aspect of the project, CFAM ensures that clients receive a fully operational and high-performing plant, ready to meet their production goals.

Global presence and impact

CFAM Technologies has established a strong presence in 18 countries across four continents. In Africa, the company plays a crucial role in supporting food security initiatives by providing affordable and nutritious solutions. In Europe and North America, CFAM focuses on delivering innovative, high-quality products tailored to competitive markets. Meanwhile, in Asia, CFAM addresses the growing demand for efficient and sustainable production systems.

Commitment to maintenance and support

CFAM’s dedication to customer satisfaction extends to its 24-hour maintenance and support services. These services ensure timely resolution of technical issues, minimising production delays and maintaining equipment efficiency. Clients benefit from regular maintenance schedules and access to experienced technicians and engineers who provide expert guidance and solutions.

Innovation and future-focused solutions

Research and development are at the core of CFAM’s operations, driving the company’s ability to remain at the forefront of extrusion technology. Sustainability is a major focus, with energy-efficient designs and renewable materials reducing environmental impact. CFAM also prioritises customisation, developing solutions tailored to specific regional and market needs. Through the integration of automation, the internet of things (IoT), and data analytics, CFAM enhances operational efficiency and provides clients with advanced control over their production processes.

A cornerstone of CFAM’s innovative approach is its dedicated Innovation Centre. This facility is designed to assist clients in developing new extruded products, refining their formulations, and finalising processing parameters before scaling up to commercial production. Clients can produce sample batches for consumer testing, gaining critical insights into market preferences and ensuring product success. The Innovation Centre serves as a collaborative hub, enabling experimentation and optimisation that reduce risks and accelerate time to market for new products. This resource underscores CFAM’s commitment to providing comprehensive support and empowering clients to excel in their industries.

Conclusion

CFAM Technologies stands as a leader in the extrusion industry, providing cutting-edge systems and turnkey solutions that empower clients to achieve their production goals. With a focus on innovation, quality, and service excellence, CFAM continues to revolutionise food processing and related industries across the globe. For more information, visit www.cfam.co.za or contact CFAM to discuss tailored solutions for your business needs.

CFAM Technologies originated as a research project within the School of Mechanical Engineering at North-West University (NWU) in South Africa. The initial focus was on developing and optimising twin-screw extrusion technology for various applications, including food processing, feed production, and industrial uses. The success of the research project and the potential commercial applications of the technology led to the establishment of CFAM Technologies in 2007. The company was founded to commercialise the twin-screw extrusion technology developed at NWU, providing high-quality, locally manufactured extrusion systems tailored to the needs of the African market and beyond. Over the years, CFAM Technologies has grown significantly, expanding its product range and customer base. The company has become known for its innovation, quality, and commitment to customer service. We have also contributed to food security and economic development in the regions we serve by providing technology that enables local production of food and other products.