Not so many years ago, bulk grain was commonly transported by rail throughout the country. However, this mode of transportation has rapidly deteriorated. Nowadays, only limited volumes are still being transported to Durban for exports and even smaller amounts from the Northern Cape to the broader Cape Town area.

The deterioration of infrastructure is probably the main cause. However, this is not the only cause, especially in the case of the Durban export corridor. Only a few wagons are loaded at a time, which then have to wait on sidings and eventually be hooked onto available trains in what appears to be a random or unplanned manner. It often takes wagons 30 days or more to reach Durban, while it should only take a couple of days.

Previously, large volumes of grain were moved through the concept of a ‘block train’. This meant, for example, that two or three batches of wagons would simultaneously be loaded at an equal number of silos in close proximity to one another and/or on the same branch line. Once loaded, the wagons would be combined into one train of approximately 50 wagons. Once the ‘block train’ had been put together, no further wagons would be added, neither would wagons be removed. The train would then follow a predetermined schedule that would take it to Durban in a couple of days. This was of course assuming that no external events impacted the movement of the train, since this cannot be controlled. If there was an external event, such as cable theft, the complete train and locomotives would wait until the problem had been resolved – often fairly quickly, half a day or less. While waiting, the wagons remained hooked to the locomotives, which were not then diverted to be used elsewhere.

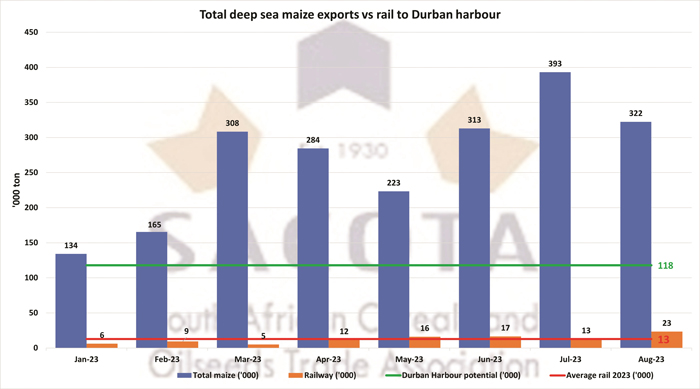

The extent of the decline in grain volumes moved by rail for export, is best depicted in Graph 1. This year an average of only 13 000 tons per month have been transported by rail. This compares to the combined harbour terminals’ capacity of 118 000 tons and exports averaging 268 000 tons. As recently as May/June 2021, Transnet Freight Rail (TFR) still managed around 55 000 to 70 000 tons per month. Admittedly, the KwaZulu-Natal floods of 11 to 13 April 2022 impacted on infrastructure capacities. However, one should note that we are not primarily focusing on capacities, but rather on the efficient placing and loading of wagons and the scheduling of trains in the timeliest manner.

In March 2023, SACOTA (the South African Cereals and Oilseeds Trade Association) proposed a block train pilot project to TFR management. The key objective was to prove that with the necessary planning, empty wagons could still be placed, loaded, combined into a block train and moved to Durban in a couple of days. In July 2023, TFR approved the pilot project and the responsibility was assigned to Ntombi Mzombi, senior operational manager, KZN.

During the project development phase, SACOTA and TFR management teams collaborated to create an execution plan. SACOTA members coordinated their efforts, providing aggregated loading instructions, tailored to a specific branch line and predetermined silos. Participating parties included Johan van Rensburg of VKB, the participating storage operator; Matthew Riethuis of Migalo, which is a SACOTA member and who coordinated the technical input; and participating exporting members, Louis Dreyfus (LDC) and COFCO, who volunteered to make stock available.

The turnaround time was eight days from the time that the empty wagons left Durban, including placement at sidings, loading at VKB Reitz and Daniëlsrus silos, being combined into the block train, and return travel to Durban until offloading at South African Bulk Terminals’ DBS export terminal. The block train itself took only two days from Bethlehem (where the loaded wagons were combined) to Durban (Island View).

This achievement not only proved that the rapid movement of bulk grains is still possible, but also underscored the potential benefit for SACOTA members and the entire grain export industry. The cost benefit of moving grain in a couple of days, compared to loaded wagons that often take 30 to 45 days until arrival and that are exposed to infestation, water damage, theft and financing, is massive. SACOTA and its members remain committed to further exploring the viability of expanding and continuing this initiative, recognising the need for clear and precise execution rules to ensure its ongoing success. The next step is for SACOTA to again engage with TFR management, although we are hopeful that they recognise the benefits and approach the industry to pursue the matter. After all, TFR is the service provider and SACOTA members and industry are the clients.

Loaded wagons’ turnaround time

There is also a second objective to the block train project: If the turnaround time of the loaded wagons can be significantly reduced, SACOTA members benefitting will contribute a small levy per ton towards expanding the security camera project. SACOTA and industry, in collaboration with TFR security, have already erected two 24-hour monitored cameras to protect the line against cable theft. In the last twelve months, there has been no theft at the spots where these cameras were erected, but there is a need to expand the project. Cable theft is probably the single biggest challenge facing TFR on the Durban export corridor.

Effective rail transport for the export market is necessary for South Africa to be internationally competitive. Rail transport is not only more cost-effective, but the traditional infrastructure for loading and offloading bulk grains was designed for rail, which could mean better loading efficiencies. The large number of grain trucks on the roads also comes at a cost, such as the deterioration of roads and an increased number of accidents.