MRL consultant, CropLife SA

South Africa is a significant role-player in international grain production. Annually millions of tons of maize, wheat and other grains are produced, helping to ensure local food security and supporting the economy via exports and international trade. However, pesticide maximum residue limits (MRLs) are currently one of the most challenging and fastest growing trade policy issues impacting global food production and trade.

The responsible use of pesticides in grain production is crucial to control a wide variety of insects, weeds and other pests and diseases. A crop that has been treated with a pesticide may contain small trace amounts of pesticide chemicals which are called residues. Residues break down over time, but some may remain in grain and other food products by the time it reaches a consumer’s plate. Regulatory authorities in most countries have therefore established MRLs and import tolerances (ITs) to regulate pesticide residues in food products to ensure that it is safe. MRLs and ITs are important trade standards which foster international food trade. Although MRLs and ITs are not safety standards, consumer safety is assessed when MRLs are set.

An MRL is the highest level of a pesticide residue that is legally allowed to remain in or on food or feed products when a pesticide is applied correctly (good agricultural practice). Import tolerance is an MRL set for imported products to facilitate international trade. An MRL and IT are set for a specific pesticide active ingredient on a specific crop, based on scientific assessments. In South Africa maximum limits for pesticide residues that may be present in foodstuffs are determined by the Foodstuffs, Cosmetics and Disinfectants Act (Act No. 54 of 1972) which is applied by the Department of Health. New and proposed MRL values are published in the Government Gazette.

To help producers comply with local MRLs, pesticide product labels indicate pre-harvest intervals (PHIs). A PHI is the minimum amount of time that must be allowed between final application of the pesticide and harvest of the crop. This helps to ensure that residues break down to levels that will not exceed the South African MRLs.

Currently there is a lack of global harmonisation of MRLs, and values can differ between countries for various reasons, including differences in the following aspects: regulatory approaches; consumer preferences and dietary intake; risk assessments; environmental and climatic conditions; and agricultural practices.

Many countries follow their own guidelines for setting MRLs, while others rely on international guidelines which are provided by the Codex Alimentarius Commission (Codex). Codex was established by the World Health Organisation and Food and Agriculture Organisation to promote fair practices in food trade and to protect consumer health. Some countries only use Codex MRLs, but many countries still choose to maintain their own national MRLs. Countries like the USA, Japan and Canada as well as the EU have very comprehensive MRL lists. Some of these also apply default MRL values (e.g., 0,01 mg/kg for the EU) if they do not have an MRL or IT for a crop-active combination.

Other countries like India and Malaysia have limited national MRL lists, but they make use of deferral paths. This means that if they do not have their own MRL for a crop-active combination, they will defer to the Codex MRL if one exists. Certain countries such as Russia have very complex deferral paths that reference multiple standards. Taiwan is an example of a country that maintains a limited national MRL list, but they have zero tolerance for any residues that are detected for which no Taiwan MRL exists. MRL gaps combined with lack of deferral paths and default MRLs can cause significant barriers to trade and governments of importing countries can even reject treated grains at the port of entry if an MRL exceedance is detected.

Sampling

To determine if residues comply with MRLs, samples of the raw or processed grain commodities can be collected from various sources (for example, farms, storage facilities, and processing plants) and sent for residue testing at an analytical laboratory. If a residue is detected which exceeds the South African MRL of the crop, then the product may legally not be traded. If grain is exported, residues must also comply with the MRLs of the importing country.

Some active ingredients which are registered for use on grains in South African have local MRLs that are significantly higher than the MRLs of some importing countries. This means that even though producers can do everything correctly, including following the pesticide product labels and complying with the local MRLs, they can still run the risk of having an MRL exceedance if they are exporting to a country that has a lower MRL. This will cause a disruption in trade as the shipment cannot be exported and traded with the importing country.

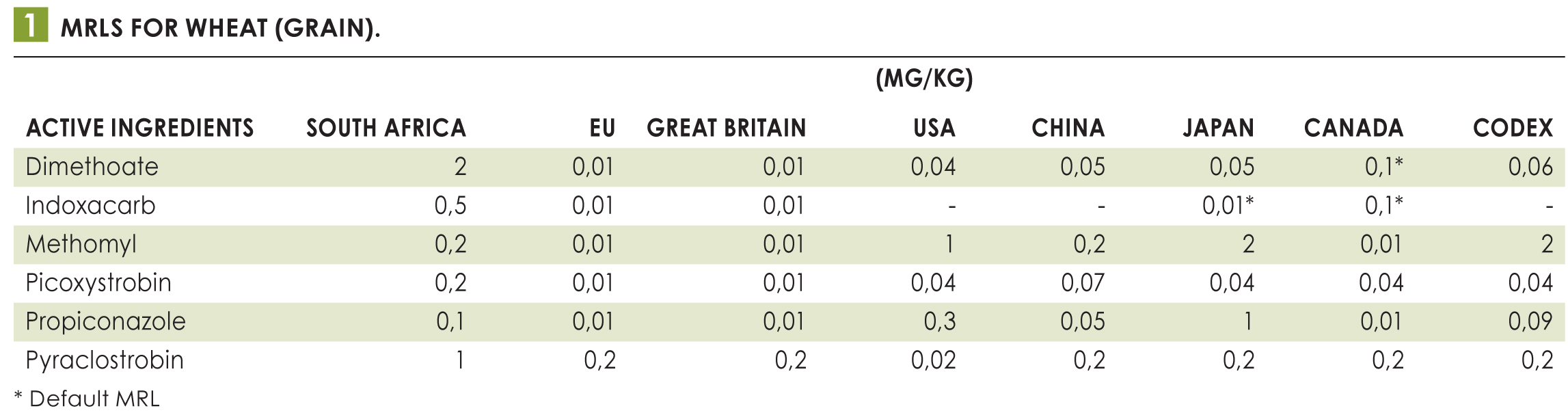

Table 1 shows a few examples of active ingredients that are registered for use on wheat (grain) in South Africa and which have local MRL values that are significantly higher than the MRLs of some of the countries to which wheat could be exported.

Many countries also review and change their MRL values frequently. It is therefore very important that growers, grower associations, and exporters familiarise themselves with the MRL values of the countries to which they are exporting and keep up to date with new and proposed MRL changes. It is important to understand the time frame of when new MRLs might become applicable and to come up with a strategic plan for crops that might be impacted negatively by MRL changes. In the case of exports, growers must keep in mind that the PHI on the pesticide label might not be sufficient to comply with a lower MRL of an importing country. Growers might need to extend the PHIs to allow residues more time to break down to levels which will not exceed the MRL of the importing country.

Many countries also review and change their MRL values frequently. It is therefore very important that growers, grower associations, and exporters familiarise themselves with the MRL values of the countries to which they are exporting and keep up to date with new and proposed MRL changes. It is important to understand the time frame of when new MRLs might become applicable and to come up with a strategic plan for crops that might be impacted negatively by MRL changes. In the case of exports, growers must keep in mind that the PHI on the pesticide label might not be sufficient to comply with a lower MRL of an importing country. Growers might need to extend the PHIs to allow residues more time to break down to levels which will not exceed the MRL of the importing country.