general manager,

SAGL NPC

Dr Dirk Strydom,

managing director,

Nampo (Pty) Ltd,

Grain SA

Marguerite Pienaar,

Marguerite Pienaar,agricultural economist, Grain SA

Maize grading is a classification system used to assess the quality of maize. In South Africa, this process is governed by the Agricultural Product Standards Act (Act No 119 of 1990) and regulated by the Department of Agriculture.

The grading helps ensure fair trade, food safety, and quality consistency across the market. Over the past season, producers have raised several questions regarding maize grading regulations – specifically how locally produced maize is graded and how this compares to grading systems used by leading maize-producing countries such as the United States.

As South Africa is a key player in maize production, local prices are also influenced by international market trends. It is therefore important to understand and compare grading systems to ensure fair competition and a level playing field in both local and global markets.

Since 1997, the South African maize industry has supported crop quality surveys through the Maize Trust. Consequently, a comprehensive database of quality metrics, encompassing data from various production seasons and geographical regions, has been developed. This dataset is publicly accessible via the website of the Southern African Grain Laboratory (SAGL).

The quality parameters included in the survey are of fundamental significance to the maize value chain. Over time, additional analyses have been incorporated to align with evolving regulatory standards and industry requirements. The sampling protocol, developed by industry stakeholders, ensures that the sample accurately represents the entire crop. Under an agreement with the grain silo industry (Agbiz Grain), each delivery is sampled and graded in accordance with established grading regulations. The graded samples are then placed in separate containers, categorised by class and grade, for each silo bin.

The contents of each container are subsequently divided using a multi-slot divider to obtain a 3 kg sample, which is then submitted to the laboratory for analysis. A selection of the samples received at the laboratory is made based on production figures provided by the Crop Estimates Committee. This methodology ensures a representative sample of each season’s production.

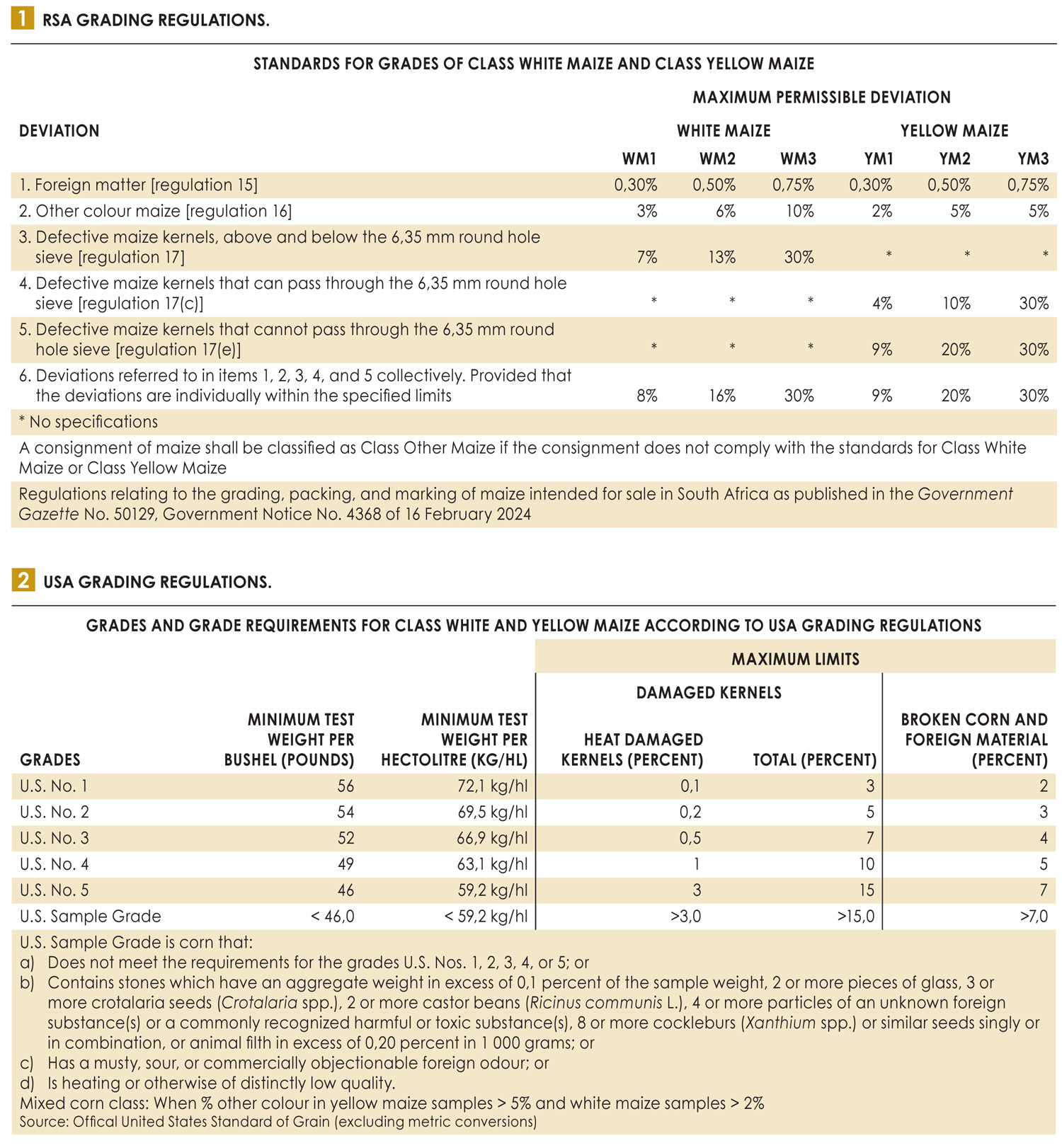

All the maize samples included in the survey are graded using both the South African grading regulations and the USA grading regulations. It is therefore possible to compare the two sets of grading results generated on the same samples. Table 1 and 2 provide some insights into the grading parameters for the two countries’ grading regulations.

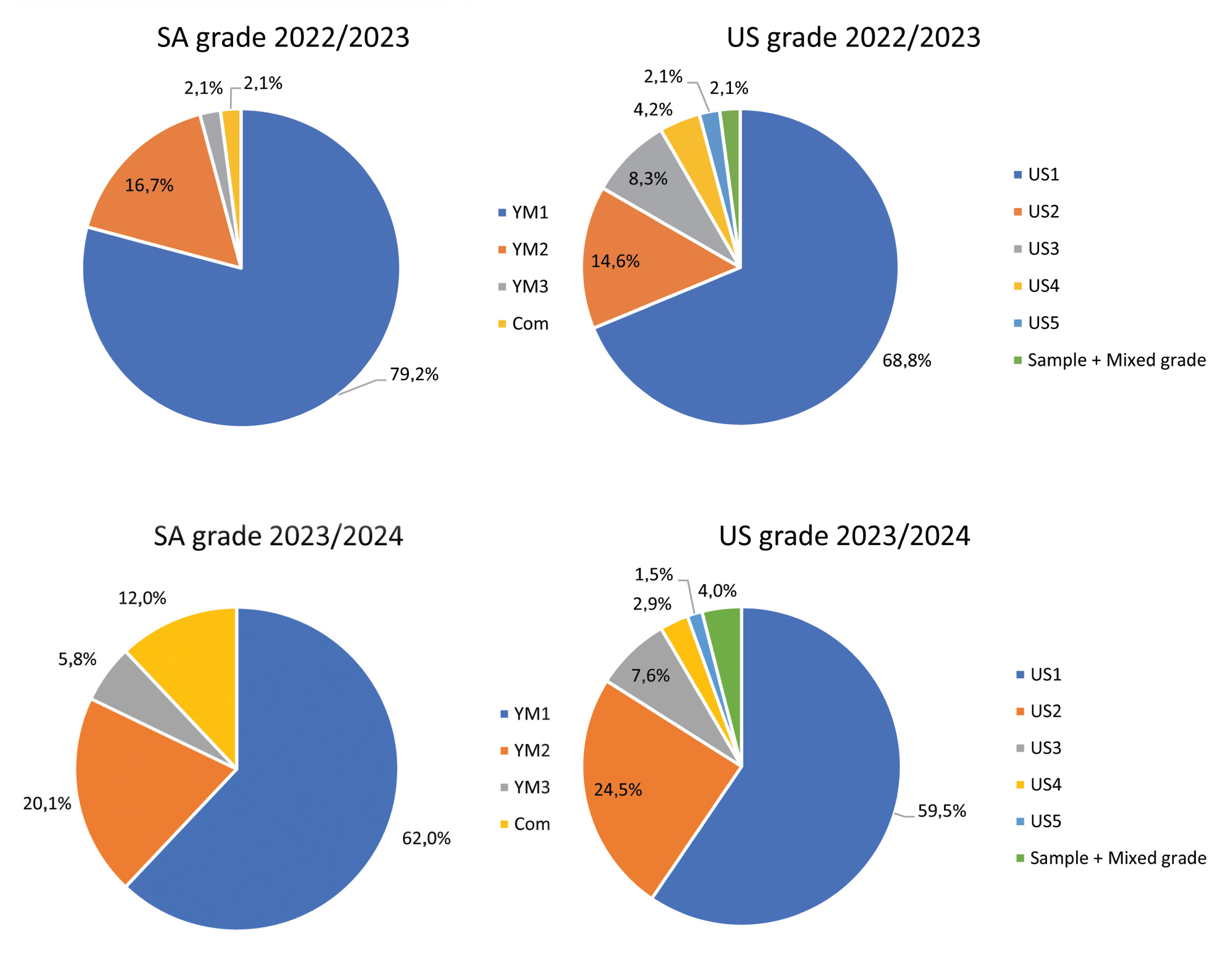

For comparative purposes and to highlight the differences observed when grading the same samples using the two grading regulations described above, summaries were compiled for yellow maize over the past twelve seasons. National averages for South Africa were used in the comparison. Figure 1 provides an example of how the data were summarised.

For comparative purposes and to highlight the differences observed when grading the same samples using the two grading regulations described above, summaries were compiled for yellow maize over the past twelve seasons. National averages for South Africa were used in the comparison. Figure 1 provides an example of how the data were summarised.

* More detailed information for other seasons and regions can be requested from the SAGL.

The comparative summaries showed that, across the 2012/2013 to 2023/2024 production seasons, only one season recorded a marginally higher proportion of U.S. Grade 1 (US1) maize compared to South African Grade 1 yellow maize (YM1). A similar analysis conducted on selected individual production regions reflected the same trend observed at the national level. These findings underscore the importance of long-term data in supporting robust and reliable comparisons. In contrast, basing conclusions on data from only three to four seasons increases the risk of inaccurate or misleading interpretations.

Understanding the maize grading system is essential for all stakeholders in the value chain – from producers and traders to processors and policymakers. Clear, consistent grading standards not only uphold product quality and food safety but also enhance market transparency and competitiveness.

Ongoing dialogue, awareness, and alignment across the industry will be crucial in ensuring that the grading system remains relevant, fair, and supportive of both domestic and export markets.