Part 1

Grain farming is a cornerstone of South Africa’s agricultural economy, contributing directly to national food security and supplying raw materials to industries such as food processing and animal feed. The sector not only sustains livelihoods and rural communities but also ensures that households across the country have consistent access to staple foods. However, these benefits come with inherent risks, particularly from the use of hazardous chemicals. Among the most significant are pesticides, herbicides, fertilisers, cleaning agents, and petrol products, which, if not managed safely, can pose serious threats to employees, communities, and the environment.

Hazardous chemicals such as pesticides, herbicides, fertilisers, and cleaning agents can have detrimental health effects on individuals working with or near them. Exposure to these hazardous chemicals may result in both acute health problems such as respiratory irritation, nausea, headaches, or skin burns and chronic conditions including asthma, skin diseases, neurological damage, long-term illness, cancer, and disability. For this reason, employees must be familiar with the types of chemicals they work with, how exposure can occur, the associated health concerns, and the occupational health and safety protocols in place. Employees should also know how and where to report any spillages, accidental exposures, or adverse health effects they may experience.

How grain farms are affected

Every grain farm should conduct a detailed risk assessment to identify hazards linked to chemicals such as pesticides, herbicides, fertilisers, cleaning chemicals, and petrol products. A key tool in this process is the safety data sheet (SDS), provided by the manufacturer or supplier. SDSs outline routes of exposure, potential health and physical hazards, control measures, recommended protective equipment, safe disposal methods, and first-aid procedures. Once these routes – whether ingestion, skin absorption, or inhalation – are understood, farms can implement more effective protective measures.

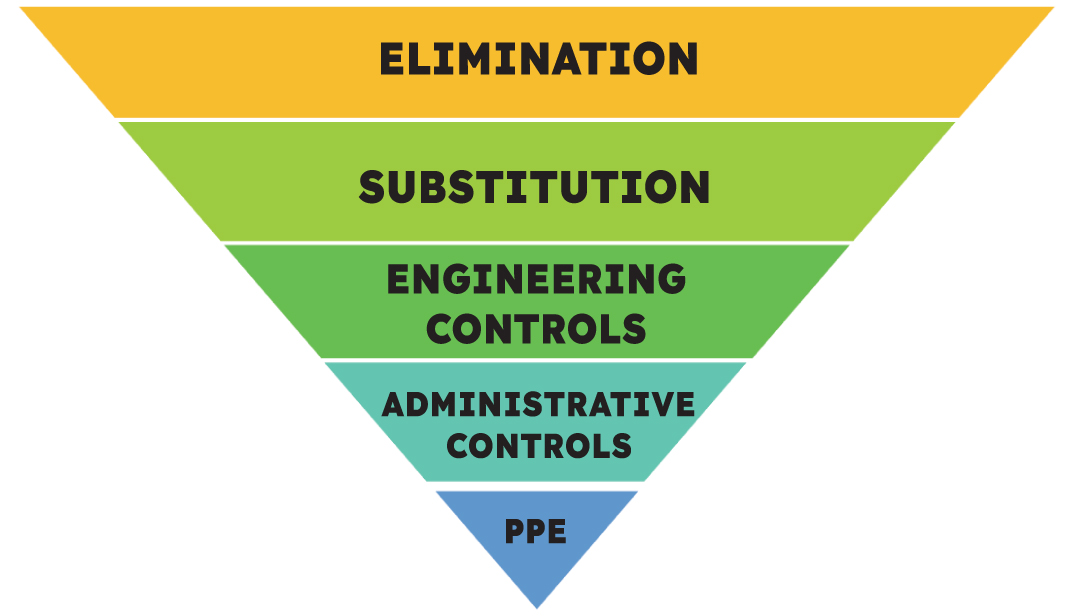

It is often tempting to focus only on personal protective equipment (PPE), but PPE should be viewed as the last line of defence. Masks, for example, may be uncomfortable and ineffective if they do not fit correctly. More effective and sustainable control measures should always be prioritised, and these are outlined in the hierarchy of control (see Figure 1).

From the risk assessment that identified the possible hazards, the roots of entry through which farm workers are exposed to hazardous chemicals can be established. Based on this information several methods to eliminate or control exposure for workers to hazardous chemicals are available. The first and most effective option is elimination, i.e., removing the hazardous chemical from the farm environment entirely. For example, some farms use mechanical weeding instead of herbicides. Where elimination is not feasible, substitution should be considered, such as replacing a chemical with a known cancer risk with one that is less harmful.

Engineering controls offer another layer of protection by physically limiting exposure. These include installing mechanical ventilation in enclosed spaces, splash guards at mixing stations, or barriers between employees and chemicals. These systems must be designed for specific situations and maintained regularly.

Administrative controls focus on policies and procedures such as activities like training and information sharing to reduce risk. Other examples include restricting access to chemical storage areas, providing structured training, scheduling spraying during safe weather conditions, and recording chemical use. While very helpful, administrative controls often rely on strict supervision and are less reliable than elimination, substitution, or engineering solutions.

Personal protective equipment (PPE)

Finally, PPE provides an important safeguard when other measures are insufficient. PPE includes respirators, gloves, goggles, and protective clothing. To be effective, PPE must fit correctly, be inspected before use, and be properly maintained. No single method from the hierarchy of control is fully effective on its own, and the best protection usually comes from a combination of measures tailored to the farm’s risks. It should be kept in mind that seldom only one control selected from the hierarchy of control will be 100% effective; usually a combination of a few methods delivers the best results.

All employees must receive comprehensive training on hazardous chemical management. Training should cover safe handling and mixing procedures, correct use of PPE and engineering controls, recognition of hazards and label information, and emergency response actions. Regular safety meetings reinforce learning, encourage reporting of unsafe conditions, and help foster a culture of safety. Employees should always feel empowered to raise concerns without fear of reprisal.

Chemical containers must remain clearly labelled throughout their lifespan, providing hazard warnings, safe handling instructions, and emergency response information. Since September 2024, the Regulations for Hazardous Chemical Agents require that all chemicals supplied to workplaces comply with the Globally Harmonised System (GHS) for classification and labelling. Labels should provide critical information about the chemical, including hazards, handling instructions, safety precautions, and emergency response actions. Producers may only accept GHS-compliant products. Farms should also use signage to mark storage areas, restricted access zones, and safety protocols.

When mixing and applying chemicals, employees should have been trained on how to follow manufacturer’s instructions precisely, use proper measuring devices to avoid spills, mix in well-ventilated areas, and apply chemicals only in favourable weather conditions. Spraying during high winds wastes chemicals, increases costs, and exposes unintended people or areas.

Chemicals must be stored in designated areas that are secure, locked when not in use, well-ventilated, dry, and away from direct sunlight or heat sources. Storage locations must also be inaccessible to unauthorised persons, especially children, and animals.

Even with proper controls, accidents can occur. Every farm should have an emergency response plan, including spill kits for immediate containment, first-aid equipment and trained first aiders on-site, emergency contact numbers displayed prominently, and clear procedures for decontamination and notifying emergency services. Regular drills and refresher training ensure employees know how to act during an incident.

Prevention is better than cure

Employees who handle hazardous chemicals must be placed under medical surveillance, as required by the Regulations for Hazardous Chemical Agents (2021). Regular monitoring enables the early detection of adverse health effects and ensures timely medical intervention. This not only protects individual employees but also safeguards the entire workforce by identifying risks early and allowing practices to be adapted accordingly.

The responsibilities of the producer are clearly set out in these regulations under the Occupational Health and Safety Act (Act 85 of 1993, as amended). Producers who need additional guidance can contact their nearest Labour Centre of the Department of Employment and Labour for additional information.

Hazardous chemicals are a necessary part of modern grain farming, but chemicals must be managed responsibly to protect employees, communities, and the environment. By conducting thorough risk assessments, applying the hierarchy of control, training employees, and ensuring compliance with regulations, farms can reduce risks significantly. Safe chemical management not only safeguards employees’ health in this sector but also strengthens the agricultural sector, protects rural livelihoods, and supports South Africa’s long-term food security.