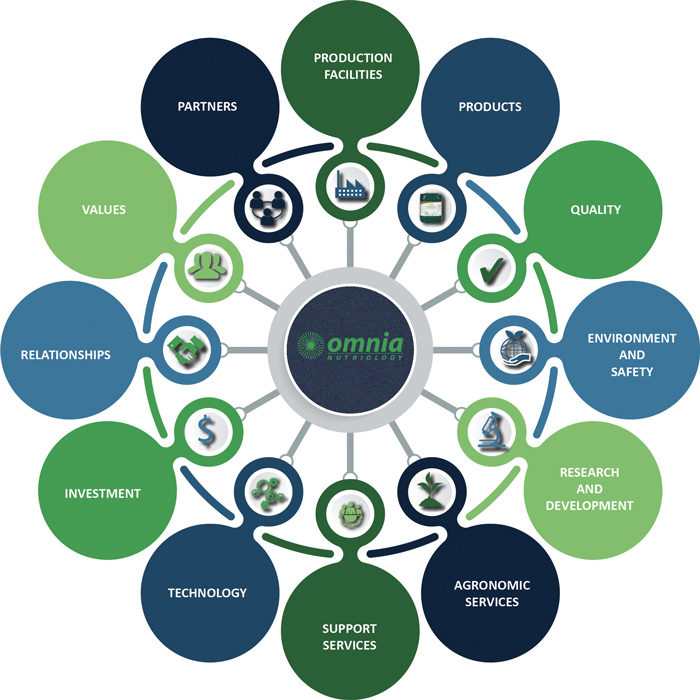

At Omnia Nutriology® we believe in a holistic approach to managing crops. This means that we take an active interest in the growth of the crop, from before planting to after the harvest. To achieve this, we apply our proven Nutriology® concept.

As part of our twelve-element Nutriology® concept, Omnia follows quality-driven processes of the highest standards. Unique skills, optimised processes, certified systems, and stringent quality control measures are utilised to ensure we manufacture products of superior quality.

Our Chemtech Quality Control laboratory plays a significant role in ensuring that our products adhere to international standards and are produced through legally compliant practices and specifications. This modern laboratory with state-of-the-art facilities incorporates the latest technologies, instrumentation and information technology, underlining its status as one of the leading fertiliser laboratories in Africa.

The Chemtech Quality Control laboratory plays a critical role in production, for both in-process and finished product testing, where the quality of all incoming raw materials used in the manufacturing process, subsequent intermediate products and all final products are tested, validated, and approved on either a continuous or batch-based basis.

Photo: Jaco du Plessis

Quality control is like safety

The key to the success of our QC laboratory is the knowledge and experience of its people. Within the environment of quality control in a continuous production environment, it is crucial to apply the ability to plan effectively, and yet be agile enough to adopt quickly to a changing environment.

Quality control procedures act like smoke detectors. Like safety, the quality control philosophy and dynamics are entrenched from the early stages of production. It has been proven that continued focus on a good quality control program prevents unfortunate events, facilitates early detection of problems, and allows for quick response when it occurs.

Also, like safety, quality control procedures need to be kept dynamic by constant revision and optimisation. This approach allows for these procedures to do exactly what it has been designed for – validate products and early detection of problems.

Photo: Jaco du Plessis

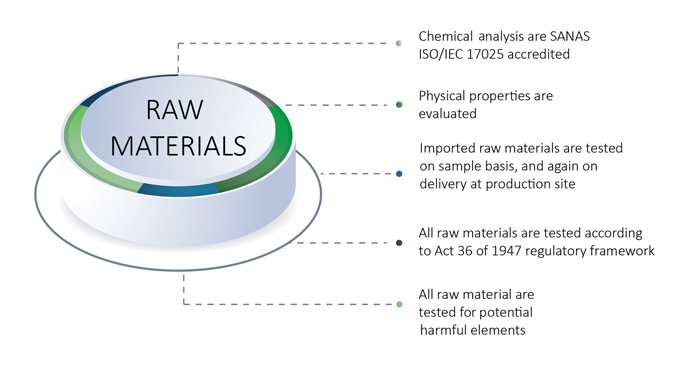

Raw materials

All raw materials used in the production of Omnia’s products, undergo testing before use.

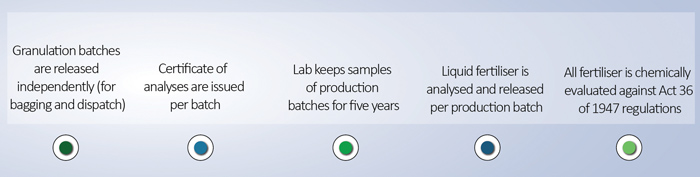

Intermediate products (products that are manufactured and used in the production process) are continuously tested during production. Real-time feedback on quality is provided to production units on a 24/7/365 basis.

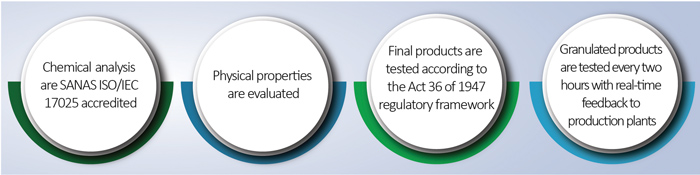

Final products

Unique to Omnia, every batch of granulated fertiliser is analysed and validated for its physical properties. These properties include tests like granular hardness, fertiliser caking tendency, granular abrasion resistance, percentage of coating, fertiliser dust formation, particle size distribution, bulk density, moisture, and granular roundness.

Frequently asked questions

- The Chemtech laboratory is operating on a 24/7/365 basis, which facilitates very quick turnaround times.

- The laboratory offers commercial fertiliser analyses and, amongst others, an Act 36 Registration Package.

- All senior staff completed the FERTASA BASOS/FACT course.

- The laboratory participates in several international proficiency schemes, including Magruder, AFPC and AgriLASA.

- Chemtech QC is used as the primary laboratory for the Grain SA/Fertasa annual fertiliser monitoring scheme.

Photo: Jaco du Plessis

Laboratory certification and accreditation

- Chemtech’s ISO/IEC 9001:2015, ISO/IEC 14001:2015 and ISO/IEC 45001:2018 certification is testimony of our commitment to deliver quality, ensure health and safety and adhere to environmental and legal requirements.

- Our international ISO/IEC 17025:2017 accreditation of fertiliser, irrigation water, heavy metal, leaf, and soil analytical methods underlines our commitment and ability to deliver fast, accurate and precise analyses.